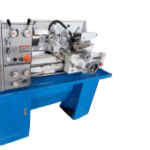

Horizontal lathe machine C6240D

Feature:

1. The surface between bed and headstock, tailstock and bed , carriage and bed….. scratched by manual, insuring the machine presition and stability.

2. The bed adopts high cast iron mixed with chromium , width of bed 312mm, guideway fired depth is up to 3mm, improving wear resistance and stability

3. Headstock lubrication adopts Cycloidal Pump forrecyling lubrication, ensuring headstock cleaning and fast heat spreading , increasethe life gear and bearing.

4. Spindle adopts bearing in the brand of WAFANGDIAN, with 52mm spindle bore, gears are with higher hardness and lower voice as adopting precision grinding,

5. Leadscrew is from China famous brand, screwnut adopts high quality bronze alloy ensuring longer life accuracy and resistance-wear.

6. With four way high strength tool post, tool size: 20x20mm

Description

| Specification | C6240D |

| Center height | 200mm |

| Max .Swing over bed | 400mm |

| Max .Swing over carriage | 210mm |

| Max .Swing in gap | 560mm |

| effective gap length | 200mm |

| Max .length of work piece | 750mm or 1000mm |

| Width of bed | 310mm |

| Spindle taper | MT6 |

| Thru-hole spindle | 52mm |

| Spindle speed | 30-1600r/min (12steps) |

| Cross Travel | 240mm |

| Compound Travel | 140mm |

| Tailstock center sleeve travel | 90mm |

| Tailstock center sleeve taper | MT4 |

| Spindle motor | 3/4kw |

| Range of metric thread(kinds) | 0.45-20mm (30kinds) |

| Range of inch thread(kinds) | 80-1.75 n/1’’ |

| Longitudinal feed per spindle rev. | 0.039-1.1mm |

| Cross feed per spindle rev. | 0.018-0.55mm |

| Overall dimensions for 750mm | 2000×1130×1540mm |

| Overall dimensions for 1000mm | 2250×1130×1540mm |

| Net weight of 750mm | 1700kg |

| Net weight of 1000mm | 1800kg |