C9350

Add to Wishlist

Add to Wishlist

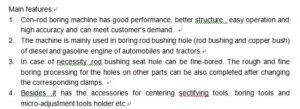

Main features:

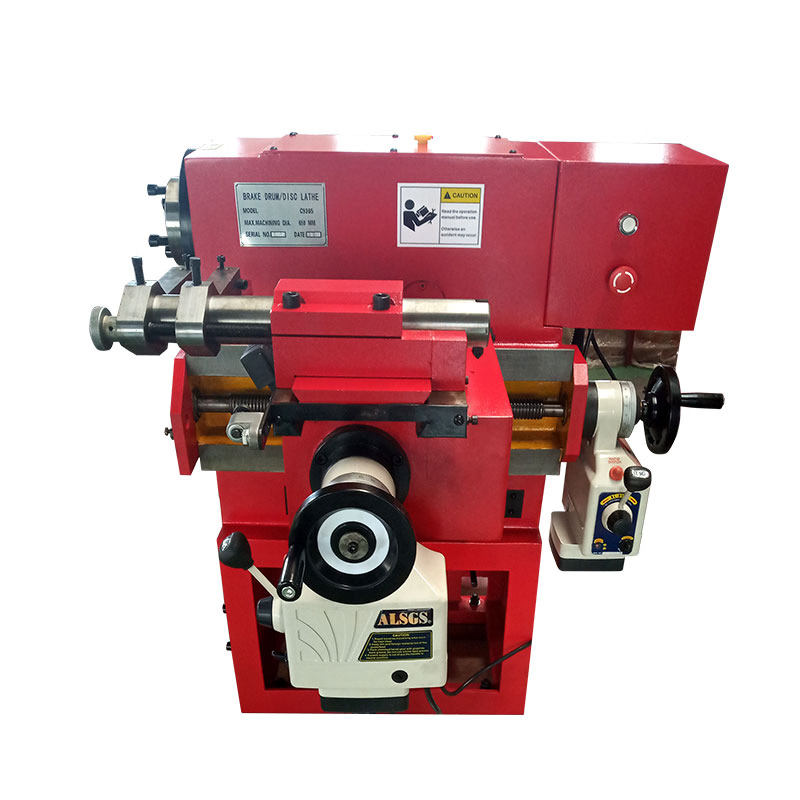

1. The machine is mainly used for boring and repairing the brake drum and plate for pick-up truck,car and mini car.

2. The machine use horizontal structure, low center of gravity and easy to clamping.

3. Use bearing outer ring of brake drum as the locating datum, use dabber and taper sleeve can easy to made clamping 、boring and repairing the brake drum come true.

4. The machine are good in rigidity,quick in cutter speed、high in efficiency.In general you only should turning one time, the machine can reach your accuracy requirement.

5. The machine is variable speed control without step,easy to operate, easy to repair, on the safe side.

Description

| Model | C9350 | |

| Range of processing | brake drum | Φ152-Φ500mm |

| Brake plate | Φ180-Φ330mm | |

| Max depth of processing brake drum | 175mm | |

| Rotor thickness | 1-7/8” (48mm) | |

| Spindle Speed | 70、80、115r/min | |

| Spindle feed speed | 0.002″-0.02″ (0.05-0.5mm)Rev | |

| Cross feed speed | 0.002″-0.02″ (0.05-0.5mm)Rev | |

| Max processing depth | 0.5mm | |

| Machine Power | 0.75kw | |

| Motor | 110V/220V/380V,50/60HZ | |

| Gross weight | 290 kg | |

| Dimension (L×W×H) | 970×920×1140mm | |