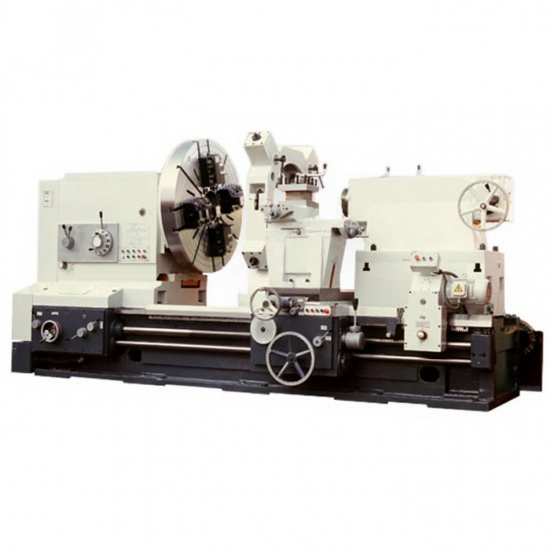

Heavy Duty Horizontal Lathe Machine CW6280B

Features:

1.The side wall of bed is constructed with coublerib plates.and the shape of internal ribs is of box type and bevel ribs combination.The rigidity is higher

than that of ordinary lathes.The precision is stable.And these lathes can carry out strong force cutting.

2.On apron,there is a device,operated by a single lever,used for rapid traverse of the carriage.braking and rotating directionchange is controlled by hy

raulic system,or by hand operation,all to the choice of users.

3.The saddle guide way is glued by “TSF” soft belt wear resisting materials.

4.On userdemand,we can equip the lathe with automatic feeding mechanism.The top slide can be used independently for turning of short cone.In com

bination with longitudinal feeding,it can also turn long taper surface.

Description

| MODEL | Unit | CW6163B CW6263B | CW6180B CW6280B | CW6194B CW6294B | |

| Swing over bed | mm | 630 | 800 | 940 | |

| Swing over carriage | mm | 350 | 520 | 660 | |

| Maximum length of workpiece | mm | 750/1000/1500/2000/3000/4000/ | 750/1000/1500/2000/3000/4000/ | 750/1000/1500/2000/3000/4000/ | |

| 5000/6000/7000/8000/9000/10000 | 5000/6000/7000/8000/9000/10000 | 5000/6000/7000/8000/9000/10000 | |||

| Maximum turning length | mm | 600/850/1350/1850/2850/3850/ | 600/850/1350/1850/2850/3850/4850 | 600/850/1350/1850/2850/3850/4850 | |

| 4850/5850/6850/7885/8850/9850 | /5850/6850/7885/8850/9850 | /5850/6850/7885/8850/9850 | |||

| Swing over gap | mm | 830 | 1000 | 1140 | |

| Effective width of gap | mm | 300 | 300 | 300 | |

| Pan of guideway | mm | 550 | 550 | 550 | |

| Spindle nose | C11 | C11 | C11 | ||

| Spindle bore | mm | 100 | 100 | 100 | |

| Taper hole of spindle | 1:20/120 | 1:20/120 | 1:20/120 | ||

| Range of spindle speeds | r/min | 7.5-1000 | 6-800 | 6-800 | |

| Number of spindle speeds | 18 | 18 | 18 | ||

| Longitudinal and cross | r/min | 64;0.1-24.32 | 64;0.1-24.32 | 64;0.1-24.32 | |

| Cross-to-long longitudinal feed rate | 1.0/2.0 | 1.0/2.0 | 1.0/2.0 | ||

| Screw pitch of leadscrew | mm | 12 | 12 | 12 | |

| Number and range of metric thread | mm | 50;1-240 | 50;1-240 | 50;1-240 | |

| Number and range of inch thread | 26;14-1 | 26;14-1 | 26;14-1 | ||

| Number and range of module thread | mm | 53;0.5-120 | 53;0.5-120 | 53;0.5-120 | |

| Number and range of diametrical pitch thread | 24;28-1 | 24;28-1 | 24;28-1 | ||

| Rapid traverse speed of carriage | mm/min | 4000 | 4000 | 4000 | |

| Max.travel of cross slide | mm | 440 | 540 | 570 | |

| Max.travel of top slide | mm | 200 | 200 | 200 | |

| Section of tool shank | mm | □32 | □32 | □32 | |

| Diameter of tailstock quill | mm | 100 | 100 | 100 | |

| Travel of tailstock quill | mm | 250 | 250 | 250 | |

| Taper hole of tailstock quill | Morse 5 | Morse 5 | Morse 5 | ||

| Main motor power | kw | 11 | 11 | 11 | |

| Machine mass | kg | 3200/3400/3700/4200/4700/5800/ | 3400/3600/3900/4400/4900/6000/ | 3900/4100/4400/4900/5400/6500/ | |

| 6800/7800/8800/9800/10800/11800 | 7000/8000/9000/10000/11000/12000 | 7500/8500/9500/10500/11500/12500 | |||

| Length | mm | 2958/3275/3725/4225/5225/6275/ | 2958/3275/3725/4225/5225/6275/ | 2958/3275/3725/4225/5225/6275/ | |

| 7355/8355/9275/11275/12275 | 7355/8355/9275/11275/12275 | 7355/8355/9275/11275/12275 | |||

| Width | mm | 1393 | 1473 | 1430 | |

| Height | mm | 1537 | 1622 | 1690 | |