KSh0.00

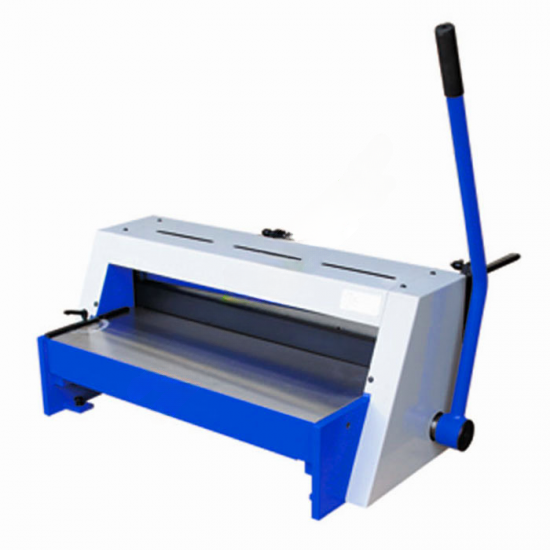

Manual shearing machine BQ01-1.25X650,BQ01-1.0X1050

Manual shearing machine Q01-1. 5×1500,Q01-1.25X2000,Q01-1.5X1050,Q01-0.8X2500

Drill bit grinder KXM10C |

| Main features: 1. Used for grinding of HSS andcarbide engraving cutters with single and multiple flutes in various shapes. 2. The cutters are held by 5C collets in the end mill grinding attachement 3. With the accessories provided the universal D bit grinder can be set up to grind end mills, slot drills and drill bits 4. For more information see the manual 5. Base, wheel mount, grinding wheel, operating tools, manual, spare parts list, test certificate, collets 3,4, 6, 8, 10mm |

Universal Tool Grinder Machine LTG200 |

|

Features: 1.For grinding of various tools, e.g. drills, millingcutters, turning tools etc. 2.Stand serially equipped with tool rest. 3.Large number of standard accessories. 4.Solid construction for vibration-free run. 5.Ergonomically arranged control elements. 6.Universal Grinder for grinding various tools, likedrills, milling cutters, turning tools, etc. 7.Wide range of applications. 8.Extensive accessories included. |

Universal Tool or drill bit Grinding Machine TG-32N |

| Features: 1) Grinding drill bits,step drill,tap,end mill face,round bars fast and accurately. 2) Grinding capacity: Dia.3mm-Dia.32mm/76mm(straight shank:3mm-32mm;Taper shankMT5#:3mm-76mm) 3) Adopts precision 6 jaw self-centering chuck. 4) When 6 jaw chuck is dismantled,the spindle hole MT5# can hold max.76mm taper shank drills. 5) Double cams adopted to save the time for changing & repairing the wheels.end mill,R type cutters and etc. |

Universal Tool or drill bit Grinding Machine TG-13D |

| Main Features: 1.Drill bit and chamfering function available 2.Grinding all straight shank drill bits with two flutes of unlimited overall length 3.Point angle and clearance angle operations 4.Easy operation.Use friendly: grinding a drill within 10 seconds. Unskilled workers can learn to sharpen the drill quickly. 5.economical price, grinding fast and high accuracy 6.High Efficiency DC motor, stable frequency, work life prolonged. |

Universal Tool or drill bit Grinding Machine U3 |

|

FEATURES: 1.it is a necessary equipment for computer engraving machine and Engraving Milling machine and CNC center. 2.it is specially designed for sharpening various diameters,shapes,angles of carving knives, round knives,straight shank cutter,end mill, lathe tool,engraving cutter and soon. 3.it is with good precision,competive price,on skill request. 4.Grinding of dies, twist drills, electrodes, gravers, livecentres etc. 5.Various angles and adjustments allow taper, cylindricaland central grinding of graving tools6.Solid construction ensures rigorous, long lastingprecision 7.Head features 24 rests for grinding of polygones on diesor electrodes 8.Wide range of standard accessories, such as chuck fortwist drills, end mills or turning tools, diamond wheel, collets as standard 9.Ideal for grinding of graving tools (engraving cutter) 10.Precisely, vibration-free driven grinding spindle guarantees optimal results |

Universal Tool or drill bit Grinding Machine 2M6420 |

| Main features: 1.Ampouleindented cutter grinding 2.End mill grinding 3.Side cutter grinding 4.T grooved mill grinding 5.Serrated mill grinding 6.Screwtap grinding 7.Hobbing cutter grinding 8.Single-angular mill grinding 9.Twist drill grinding 10.Full back cutter grinding 11.Side set mill grinding 12.Cylindrical mill grinding 13.Lathe tool grinding 14.Reamer grinding 15.Pinion cutter grinding |

Universal Tool or drill bit Grinding Machine TG-600F,TG-800F

CNC Lathe Machine UTK36

Mini CNC Lathe Machine UTCK300

Mini CNC Lathe Machine UTCK400

CNC Lathe machine CK6152E

CNC Lathe machine TCK6340S

CNC Lathe Machine CK6150

1.Big torque, high precision spindle;

2.Hydraulic chuck, easy to operate;(Optional)

3.Z-Axis feed is directly connected which hashigh transmission accuracy and high positioning accuracy;

4. Vertical4-position electric tool post with high positioning accuracy; Shank size:25x25mm. Optional six-station electric knife5. Themachine is made of high strength cast iron with special material of copper andchrome. The width of bed guide is 400mm, the firing depth of bed guide rail is 4mm, which improvesthe abrasion resistance and stability of the machine.

6.HERG Centralized lubrication from Japan;

7.BAOTN Coolant system from Taiwan.

8. X-axisand Z-axis feed movement are servo motor drive precision ball screw to achievefast-forward and feed movement. The machine adopts the Hanjiang ball screw,Z-axis ball screw(Dia.50mm), X-axis(Dia.25mm) ball screw with tensilestructure, improve the accuracy of the workpiece machining cylindrical and boresize 9. UsingChinese famous brand Wafangdian bearings, spindle hole 52mm, the machine usesbelt-driven stepless transmission, reducing machine noise and vibration10.Machine use ISO international standard CNCG code, while compatible with Japan Fanuc (FANUC) CNC system. Domesticmain stream programming, to facilitate the operator faster and easier to use thesystem.

11.The CNC system isGSK980TDC, With both horizontal and vertical structure. With 8.4-inch colorLCD, can control five feed axises (including Cs axis), 2 analog spindle, theminimum order unit of 0.1μm. PLC ladderdrawing showing, monitor, New function of soft keys, graphical interface design, the dialog box type operation, friendly man-machine interface 12.Version in Chinese,English, Spanish, Russian, Portuguese are available .With more function ofsystem time and warning log . 13.System programwith 40M, 384 program , editing function: index, modify, and delete 14.Program form: ISOCODE, support editing working including 15.Macro programming statements type, support the relative coordinates, the absolute coordinate andhybrid coordinate programming; 16.Systems support RS232 interface: parts program, two-way transmission parameters such as files,support for PLC program, the system software upgrade serial and USB interface:U disk file operations, U disk file processing, directly support the PLC program, USB system software upgrade.UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts