KSh0.00

Electric power feed ALGS series

Universal milling machine X6332C

Universal milling machine UTX6336

Universal milling machine LM1260

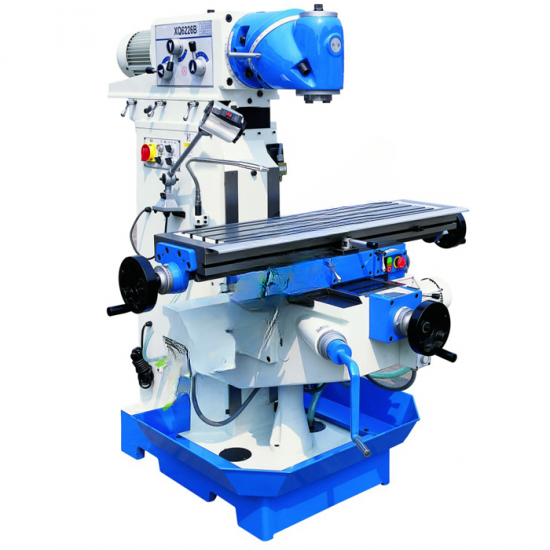

Universal milling machine XQ series

| Main Features: 1.Heavy machine frame with wide, adjustable dovetail guides in all axes 2.Rigid universal cutter head, can be moved to virtually any spatial angle on twolevels 3.Automatic table feed on X and Y axes, including rapid feed 4.Motorized height adjustment in Z direction 5.Head can rotate in different angle for using Horizontal arbors 6.spindle speed changed by ram box. |

Universal milling machine XZ6326 |

| Main Features: 1.Automaticspindle feed 2.Workingconditions :milling/drilling, tapping 3.Vertical/Horizontalmilling/drilling 4.Highrigidity 5.X-axismechanical power feed standard. 6.Vertical head with auto-feeding spindle just like Vertical drill machine. 7. Multi-purpose functions for thismachine. |

Universal milling machine XZ6350ZR |

| Main Features: 1. all 3 axis with automatic feed and rapidfeeds 2. vertical head swivels ± 45° 3. spindle speeds for horizontal and vertical spindlecontrolled by separate switch gears with oil-bath lubrication 4. capstan-controlled quill feed fordrilling, manual micro-feed for milling 3 automatic quill feeds 5. for horizontal spindle operations, thetop beam including head can be completely rotated on the stand 6. adjustable ground dovetail guideways onthe X-axis and wide square guideways on Y 7. clamping device in all 3 axes 8. adjustable stops for drilling depth andtable adjustment 9.worktable swivel +-45 standard. |

Universal milling machine X6136

Universal milling machine X6136 |

| Main Features:

1.Rectangular column guide way 2.Table can swivel +45 degrees. 3.Table size 1600*320mm is optional. 4. X/Y/Z axis is centralized automatic feeding by one gear box. 5. Vertical head is standard. 6.Horizontal is spindle ISO50, vertical head is ISO40 7.Vertical cutter head swivels and can easily be disassembled and handled via a machine-mounted bracket 8.standard equipment cover coolant, chip tray and central lubrication system. |

Universal Milling Machine XL6436

Universal Milling Machine XL6436 |

|

Features: 1.Extremely rigid machine bed made of high-strengthHT-200 cast-iron with heavy ribbing; 2.Precision-ground guide ways with hardened surfaces for long-term accuracy andwear-resistance; 3.Large work area of 1600 x 360 mm and up to 500 kg table load capacity 4.Quiet, precision-made headstock gears with hardened and ground gears 5.Universal cutter head swivels on 2 levels - quick change-over from horizontalto vertical machining 6.By combining both swivel levels, almost any spatial angle can be set 7.Powerful axis servo-motors allow infinite adjustment of feeds on all 3 axes 8.Telescoping covers on the Y axis protect the feed spindle 9.Control panel swings out to either side and features an integrated positionindicator 10.5.5 kW main drive guarantees high torque 11.Coolant system and chip tray are Included |

X6432,X6432B

Universal Milling Machine X6432,X6432B |

| Features: 1. Ball screws can be ordered instead ofstandard lead screws at special request. 2. Vertical and Horizontal spindle hole taperboth are ISO50. 3. The milling head can swivel at 360°. 4. Rotary table can be ordered at specialrequest. 5. Worktable feed on X,Y,Z by manual orautomatic. 6. Big worktable load. 7. CE standard can be chose. 8. Schneider electric can be ordered at specialrequest. 9. More stronger type. |

Universal Knee-type Milling Machine X6032A

Universal Knee-type Milling Machine X6032A |

| Feature: Rectangulartable guideways with high stability Hardenedand ground table surface Automaticfeeds on X,Y axes, motorized lifting and lowering of table on Z axis |

Drill bit grinder KXM10C |

| Main features: 1. Used for grinding of HSS andcarbide engraving cutters with single and multiple flutes in various shapes. 2. The cutters are held by 5C collets in the end mill grinding attachement 3. With the accessories provided the universal D bit grinder can be set up to grind end mills, slot drills and drill bits 4. For more information see the manual 5. Base, wheel mount, grinding wheel, operating tools, manual, spare parts list, test certificate, collets 3,4, 6, 8, 10mm |

Universal Tool Grinder Machine LTG200 |

|

Features: 1.For grinding of various tools, e.g. drills, millingcutters, turning tools etc. 2.Stand serially equipped with tool rest. 3.Large number of standard accessories. 4.Solid construction for vibration-free run. 5.Ergonomically arranged control elements. 6.Universal Grinder for grinding various tools, likedrills, milling cutters, turning tools, etc. 7.Wide range of applications. 8.Extensive accessories included. |

Universal Tool or drill bit Grinding Machine TG-32N |

| Features: 1) Grinding drill bits,step drill,tap,end mill face,round bars fast and accurately. 2) Grinding capacity: Dia.3mm-Dia.32mm/76mm(straight shank:3mm-32mm;Taper shankMT5#:3mm-76mm) 3) Adopts precision 6 jaw self-centering chuck. 4) When 6 jaw chuck is dismantled,the spindle hole MT5# can hold max.76mm taper shank drills. 5) Double cams adopted to save the time for changing & repairing the wheels.end mill,R type cutters and etc. |

Universal Tool or drill bit Grinding Machine TG-13D |

| Main Features: 1.Drill bit and chamfering function available 2.Grinding all straight shank drill bits with two flutes of unlimited overall length 3.Point angle and clearance angle operations 4.Easy operation.Use friendly: grinding a drill within 10 seconds. Unskilled workers can learn to sharpen the drill quickly. 5.economical price, grinding fast and high accuracy 6.High Efficiency DC motor, stable frequency, work life prolonged. |

Universal Tool or drill bit Grinding Machine U3 |

|

FEATURES: 1.it is a necessary equipment for computer engraving machine and Engraving Milling machine and CNC center. 2.it is specially designed for sharpening various diameters,shapes,angles of carving knives, round knives,straight shank cutter,end mill, lathe tool,engraving cutter and soon. 3.it is with good precision,competive price,on skill request. 4.Grinding of dies, twist drills, electrodes, gravers, livecentres etc. 5.Various angles and adjustments allow taper, cylindricaland central grinding of graving tools6.Solid construction ensures rigorous, long lastingprecision 7.Head features 24 rests for grinding of polygones on diesor electrodes 8.Wide range of standard accessories, such as chuck fortwist drills, end mills or turning tools, diamond wheel, collets as standard 9.Ideal for grinding of graving tools (engraving cutter) 10.Precisely, vibration-free driven grinding spindle guarantees optimal results |

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts