KSh0.00

Universal milling machine X6332C

Universal milling machine UTX6336

Universal milling machine LM1260

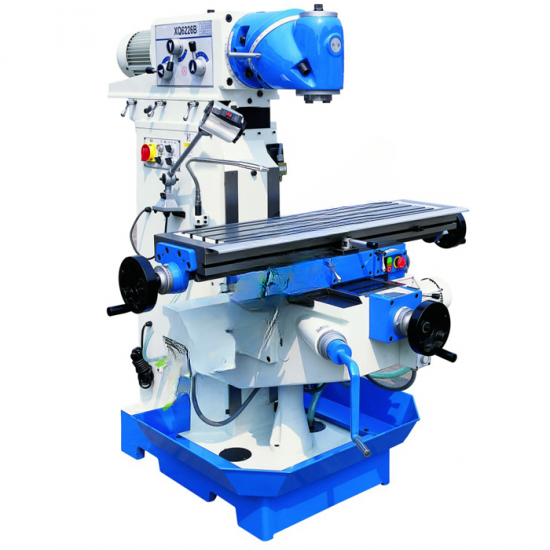

Universal milling machine XQ series

| Main Features: 1.Heavy machine frame with wide, adjustable dovetail guides in all axes 2.Rigid universal cutter head, can be moved to virtually any spatial angle on twolevels 3.Automatic table feed on X and Y axes, including rapid feed 4.Motorized height adjustment in Z direction 5.Head can rotate in different angle for using Horizontal arbors 6.spindle speed changed by ram box. |

Universal milling machine XZ6326 |

| Main Features: 1.Automaticspindle feed 2.Workingconditions :milling/drilling, tapping 3.Vertical/Horizontalmilling/drilling 4.Highrigidity 5.X-axismechanical power feed standard. 6.Vertical head with auto-feeding spindle just like Vertical drill machine. 7. Multi-purpose functions for thismachine. |

Universal milling machine XZ6350ZR |

| Main Features: 1. all 3 axis with automatic feed and rapidfeeds 2. vertical head swivels ± 45° 3. spindle speeds for horizontal and vertical spindlecontrolled by separate switch gears with oil-bath lubrication 4. capstan-controlled quill feed fordrilling, manual micro-feed for milling 3 automatic quill feeds 5. for horizontal spindle operations, thetop beam including head can be completely rotated on the stand 6. adjustable ground dovetail guideways onthe X-axis and wide square guideways on Y 7. clamping device in all 3 axes 8. adjustable stops for drilling depth andtable adjustment 9.worktable swivel +-45 standard. |

Universal milling machine X6136

Universal milling machine X6136 |

| Main Features:

1.Rectangular column guide way 2.Table can swivel +45 degrees. 3.Table size 1600*320mm is optional. 4. X/Y/Z axis is centralized automatic feeding by one gear box. 5. Vertical head is standard. 6.Horizontal is spindle ISO50, vertical head is ISO40 7.Vertical cutter head swivels and can easily be disassembled and handled via a machine-mounted bracket 8.standard equipment cover coolant, chip tray and central lubrication system. |

Universal Milling Machine XL6436

Universal Milling Machine XL6436 |

|

Features: 1.Extremely rigid machine bed made of high-strengthHT-200 cast-iron with heavy ribbing; 2.Precision-ground guide ways with hardened surfaces for long-term accuracy andwear-resistance; 3.Large work area of 1600 x 360 mm and up to 500 kg table load capacity 4.Quiet, precision-made headstock gears with hardened and ground gears 5.Universal cutter head swivels on 2 levels - quick change-over from horizontalto vertical machining 6.By combining both swivel levels, almost any spatial angle can be set 7.Powerful axis servo-motors allow infinite adjustment of feeds on all 3 axes 8.Telescoping covers on the Y axis protect the feed spindle 9.Control panel swings out to either side and features an integrated positionindicator 10.5.5 kW main drive guarantees high torque 11.Coolant system and chip tray are Included |

X6432,X6432B

Universal Milling Machine X6432,X6432B |

| Features: 1. Ball screws can be ordered instead ofstandard lead screws at special request. 2. Vertical and Horizontal spindle hole taperboth are ISO50. 3. The milling head can swivel at 360°. 4. Rotary table can be ordered at specialrequest. 5. Worktable feed on X,Y,Z by manual orautomatic. 6. Big worktable load. 7. CE standard can be chose. 8. Schneider electric can be ordered at specialrequest. 9. More stronger type. |

Universal Knee-type Milling Machine X6032A

Universal Knee-type Milling Machine X6032A |

| Feature: Rectangulartable guideways with high stability Hardenedand ground table surface Automaticfeeds on X,Y axes, motorized lifting and lowering of table on Z axis |

MY820,MY1022,MY1224,MY1230

Saddle moving surface grinding machine MY820,MY1022,MY1224,MY1230 |

| Main Features: 1.Hydraulic longitudinal table travel 2.Quality castings and Precision ball bearing supporting the spindle 3.Coolant system with nozzle and flow control valve 4.Castiron machine body and stand for maximum rigidity and smooth operation 5.Vertical dial graduations 0.01mm 6.Cross travel graduations 0.02mm 7.Manual one shot lubrication pump 8.Wheel balancing stand and arbor 9.Halogen work light |

SG-2050AH,SGA-2550AHR

Saddle moving surface grinder SG-2050AH,SGA-2550AHR |

| Main features: 1. Plastic-coated counter guide inx- and y-axis assure a low slip-stick-effect 2. V-flat longitudinal tableguide, double-V cross table guide 3. Spindle features axial andradial, clearance-free, pre-tensioned bearings 4. Seperate hydraulic unit withheat exchanger to omit vibrations and thermal load 5. Special hydraulic systemguarantees gentle table adjustment even at full load 6. Solidly constructed and wellsupported structure assures high stability 7. Digitally controlled, automaticvertical feed with servo motor 8. Infeed via rapid feed to heightof workpiece, adjustable to finishing and sparking, automatic lift at programend 9. Adjustable longitudinal andcross table movement via end stops |

SGA3063,30100,4080,40100AH/AHR/AHD

Saddle moving surface grinder SGA3063,30100,4080,40100AH/AHR/AHD |

| Main features:

1. Designed for continuous operation at maximum speed, very quiet operation,maximum accuracy and minimal heat accumulation ensure optimum machining results 2. Grinding spindle runs in maintenance-free preloaded precision angular ballbearings 3. Automatic transverse and longitudinal feed 4. Rapid feed for setup to desired work height(HFS VC) 5. Adjustable roughing, finishing, and spark-out strokes hydrauliclongitudinal table movement on Y axis(HFS VC) 6. Double table V-guide in transverse table, V-guide and flat guides inlongitudinal table 7. Table guide ways are hardened, ground, andPTFE(polytetrafuorethylene)counterlaminated-ensuring maximum wear resistance 8. High table load capacity for heavy parts 9. External hydraulic unit ensures high temperature stability 10. Automatic central lubrication |

SG50100/50160/60120

Saddle moving surface grinder SG50100/50160/60120 |

| Main features: 1. Hardened and polished table guides cross and longitudinal. Durcite-B coated counter guides ensure high rigidity and low friction 2. Longitudinal and cross movement takes place via V-flat guiding 3. Computer automated feed via rapid feed to workpiece height,adjustable roughing and surface 4. Finishing stroke, automatic return into start position at end ofprogram 5. Axial and radial bearings in grinding spindle are clamped clearancefree 6. Annealed machine base guarantees high accuracy 7. Strong reinforcements and thick walls ensure rigidity 8. End stops allow adjustable longitudinal and cross travel 9. State of the art hydraulic system guarantees soft table traverseeven at high work load 10. Central lubrication of all guide rails and spindles |

TDS-125/150/200/250

TDS series bench grinder |

| Main features: 1. Reliable and silent inductionmotors with ball bearing 2. Accept both wire wheel andgrinding wheel 3. Equipped with adjustable workrest and safety glass 4. Targeted for hobby to professionals 5. Three phase available for 8 and10 inch 6. Lamp available for all line |

GS-A/B/C/E

Bench grinder stand GS-A/B/C/E |

| Main features: GS-A 1. Cast iron base 2. Cast iron table GS-B 1. Cast iron base 2. Large steel table 3. Water tank 4. Power hook GS-C 1. Cast iron base 2. Steel frame 3. Water tank/tool box 4. Wheel storage GS-E 1. Height adjustable 2. Cast iron base 3. Large steel table 4. Water tank and tool box 5. Wheel storage |

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts