KSh0.00

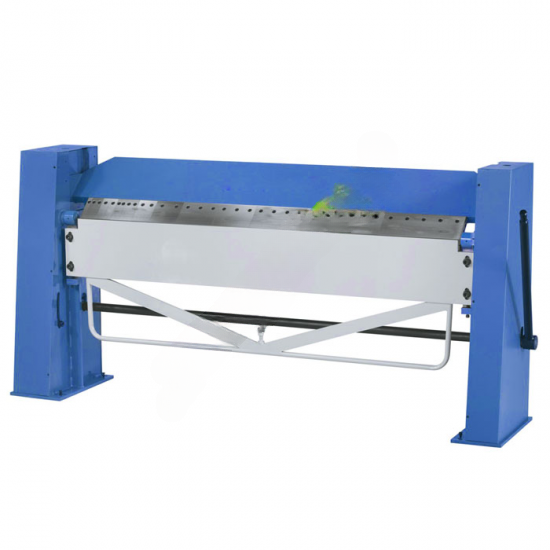

Manual folding machine PBB1020-1A,PBB1250-1A

Manual folding machine PBB1020-2.5,PBB1270-2,PBB1520-1.5

Features:

1.For formed component bending. 2.Afully welded structure, and compact high quality engineering, ensure minimummaintenance, together with simple and safe operation. 3.Havethe function of air spring which can be installed inside the arm(Optional). 4.Adjustablebending angle stop with scale up to 135° 5.Withfoot control. It is easy for operation and relax hands. 6.Segmentedtop beam tools.Manual folding machine PBB2020-1.2;PBB2520-1.0

Features:

1.For formed component bending. 2.Afully welded structure, and compact high quality engineering, ensure minimummaintenance, together with simple and safe operation. 3.Havethe function of air spring which can be installed inside the arm(Optional). 4.Adjustablebending angle stop with scale up to 135° 5.Withfoot control. It is easy for operation and relax hands. 6.Segmentedtop beam tools.Manual folding machine PBB1020-2A,PBB1270-2A,PBB1520-1.5A

Features:

1.With foot control. It is easy for operation andrelax hands for adjusting the material. 2.Compression spring for top counter balance. 3.Cam lock and rebound spring for bending beamcounter balance. 4.Bow handle for bending beam rotation. 5.Adjustable bending angle stop with scale up to 135degrees. 6.Segmented top beam tools. 7.Have the function of air spring which can beinstalled inside the arm(optional)Manual folding machine PBB1020-3SH;PBB1270-3SH

| Model | PBB1020/3SH | PBB1270/3SH |

| Max.working length(mm) | 1020 | 1270 |

| Max.sheet thickness(mm) | 2.0 | 1.5 |

| Max.clamping bar lift(mm) | 45 | 45 |

| Folding angle | 0-150° | 0-150° |

| Packing size(mm) | 1420x590x1420 | 1670x660x1420 |

| N.W./G.W.(kg) | 430/470 | 465/510 |

36;40;48;72 Inch Brake

- Includes floor stand.

- Compact design.

- Specially designed for light gauge sheet metal work.

Foot Control Folding Machine MFS 2020,MF 3020

Folding Machine TSB 2020-2

Folding Machine TSBS 2020-2,TSBS 2540-1.5,TSBS 3020-1.2

1.Universally applicable bending machine for panel-beater and repair shops.

2.Solid steel-welding-construction with modern design.

3.Manuel bending machine for standard bending tasks.

4.Quick and easy bending process using handle.

5.Easy adjustment of the lower jowl to the respective sheet thickness.

6.High upper jowl for manufacturing of profiles set on the edge.

7.Opening and closing of the upper jowl using lever.

8.The segments of the sharp rail begin at 25 mm (25 / 30 / 35 / 40 / 45 / 50 / 75 / 100 / 150/ 200 / 300 / 500 / 510 mm).

Folding Machine WF1.0X2020,WF1.0X2500,WF1.0X3000

Folding Machine TFS2020B

Folding Machine TSB 2060-2

MY820,MY1022,MY1224,MY1230

Saddle moving surface grinding machine MY820,MY1022,MY1224,MY1230 |

| Main Features: 1.Hydraulic longitudinal table travel 2.Quality castings and Precision ball bearing supporting the spindle 3.Coolant system with nozzle and flow control valve 4.Castiron machine body and stand for maximum rigidity and smooth operation 5.Vertical dial graduations 0.01mm 6.Cross travel graduations 0.02mm 7.Manual one shot lubrication pump 8.Wheel balancing stand and arbor 9.Halogen work light |

SG-2050AH,SGA-2550AHR

Saddle moving surface grinder SG-2050AH,SGA-2550AHR |

| Main features: 1. Plastic-coated counter guide inx- and y-axis assure a low slip-stick-effect 2. V-flat longitudinal tableguide, double-V cross table guide 3. Spindle features axial andradial, clearance-free, pre-tensioned bearings 4. Seperate hydraulic unit withheat exchanger to omit vibrations and thermal load 5. Special hydraulic systemguarantees gentle table adjustment even at full load 6. Solidly constructed and wellsupported structure assures high stability 7. Digitally controlled, automaticvertical feed with servo motor 8. Infeed via rapid feed to heightof workpiece, adjustable to finishing and sparking, automatic lift at programend 9. Adjustable longitudinal andcross table movement via end stops |

SGA3063,30100,4080,40100AH/AHR/AHD

Saddle moving surface grinder SGA3063,30100,4080,40100AH/AHR/AHD |

| Main features:

1. Designed for continuous operation at maximum speed, very quiet operation,maximum accuracy and minimal heat accumulation ensure optimum machining results 2. Grinding spindle runs in maintenance-free preloaded precision angular ballbearings 3. Automatic transverse and longitudinal feed 4. Rapid feed for setup to desired work height(HFS VC) 5. Adjustable roughing, finishing, and spark-out strokes hydrauliclongitudinal table movement on Y axis(HFS VC) 6. Double table V-guide in transverse table, V-guide and flat guides inlongitudinal table 7. Table guide ways are hardened, ground, andPTFE(polytetrafuorethylene)counterlaminated-ensuring maximum wear resistance 8. High table load capacity for heavy parts 9. External hydraulic unit ensures high temperature stability 10. Automatic central lubrication |

SG50100/50160/60120

Saddle moving surface grinder SG50100/50160/60120 |

| Main features: 1. Hardened and polished table guides cross and longitudinal. Durcite-B coated counter guides ensure high rigidity and low friction 2. Longitudinal and cross movement takes place via V-flat guiding 3. Computer automated feed via rapid feed to workpiece height,adjustable roughing and surface 4. Finishing stroke, automatic return into start position at end ofprogram 5. Axial and radial bearings in grinding spindle are clamped clearancefree 6. Annealed machine base guarantees high accuracy 7. Strong reinforcements and thick walls ensure rigidity 8. End stops allow adjustable longitudinal and cross travel 9. State of the art hydraulic system guarantees soft table traverseeven at high work load 10. Central lubrication of all guide rails and spindles |

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts