KSh0.00

M7130A,M7130B,M7130C,M7132

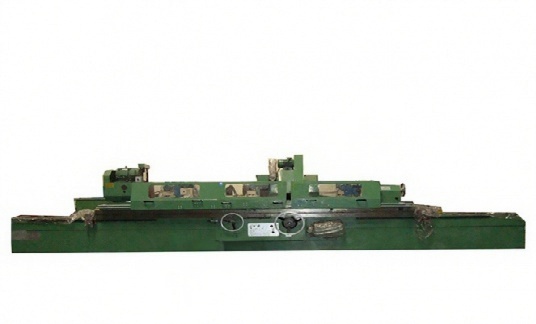

Wheel Head Moving Surface Grinding Machine M7130A,M7130B,M7130C,M7132 |

| Main features: 1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting 2.Grind wheel head spindle front end adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity,specially for heavy-duty cutting. 3.Transmission: Worktable adopts one flat andone V guide ways, driven by hydraulic with smooth movement. 4.Grinding wheel adopts two sets of guideway, one is flat guide way for up/down moving. 5.Another set is swallow tail guide way forback-forward movements, with manual feeding or Auto-feedingby hydraulic cylinder. 6.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank. The temperature of the oil tank raises little so the thermal distortion of the machine is small. 7. Full lubrication system ensuring all guide ways smooth moving. |

M7140A,M7130A

Wheel Head Moving Surface Grinding Machine M7140A,M7130A |

| Main features: 1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting 2.Grind wheel head spindle frontend adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity, specially for heavy-duty cutting. 3.Transmission: Worktable adopts one flat and one V guide ways, driven by hydraulic with smooth movement. 4.Grinding wheel adopts two setsof guide way, one is flat guide way for up/down moving. 5.Another set isswallow tail guide way for back-forward movements, with manual feeding or Auto-feeding byhydraulic cylinder. 6.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank. The temperature of the oil tank raises little so the thermal distortion of the machine is small. 7.Full lubrication system ensuring all guide ways smooth moving. |

Wheel Head Moving Surface Grinding Machine M7180 |

| Main features: 1. BallLead screw used for forward and back feeding., also worktable 2. Table with Turcite “B” for longer time life. 3. Bigbore oil cylinder adopted for better processing ability. 4. Wheel Head moving type. 5.Individual hydraulic station design. 6. Coolant and complete lubrication available |

M7150A,M7163

Wheel Head Moving Surface Grinding Machine M7150A,M7163 |

| Main features: 1. Ball Lead screw used for forward and back feeding.,also worktable 2. Table with Turcite “B” for longer time life. 3. Big bore oil cylinder adopted for better processingability. 4. Wheel Head moving type. 5. Individual hydraulic station design. 6. Coolant and complete lubricationavailable |

CNC internal grinding machine M2110CNC

| Feature | |

| NC control with English display | |

| Belt driven spindle | |

| lighting system LED type, IP65 | |

| facility of auto lubrication syste for guide ways and screw | |

| coolant tank | |

| coolant flow from work spindle end facility | |

| backlight in operator panel | |

| cross roller guide ways for feeding axis | |

| machine should be suitable for tool rom work and production work | |

| roll dressing system for profril dressing |

UNIVERSAL CYLINDARCAL GRINDING MACHINE M1408X300

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1420X800

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1450

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1463

| 1.The left and right guide rail adopts P-V structure, which is scraped by high precision manual, sothat the whole system products have high precision and high stability. 2.The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure 3.Classic control mechanism, simple, safe and reliable. 4.M1350, M1450, M1363 series worktable and grinding wheel guide rail adopts high stablehydrostatic guide rail, high rigid dynamic and static pressure spindle. 5.Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt tochuck grinding internal and external conical workpiece. |

CNC Cylindrical Grinding Machine

CNC Lathe Machine UTK36

Mini CNC Lathe Machine UTCK300

Mini CNC Lathe Machine UTCK400

CNC Lathe machine CK6152E

CNC Lathe machine TCK6340S

CNC Lathe Machine CK6150

1.Big torque, high precision spindle;

2.Hydraulic chuck, easy to operate;(Optional)

3.Z-Axis feed is directly connected which hashigh transmission accuracy and high positioning accuracy;

4. Vertical4-position electric tool post with high positioning accuracy; Shank size:25x25mm. Optional six-station electric knife5. Themachine is made of high strength cast iron with special material of copper andchrome. The width of bed guide is 400mm, the firing depth of bed guide rail is 4mm, which improvesthe abrasion resistance and stability of the machine.

6.HERG Centralized lubrication from Japan;

7.BAOTN Coolant system from Taiwan.

8. X-axisand Z-axis feed movement are servo motor drive precision ball screw to achievefast-forward and feed movement. The machine adopts the Hanjiang ball screw,Z-axis ball screw(Dia.50mm), X-axis(Dia.25mm) ball screw with tensilestructure, improve the accuracy of the workpiece machining cylindrical and boresize 9. UsingChinese famous brand Wafangdian bearings, spindle hole 52mm, the machine usesbelt-driven stepless transmission, reducing machine noise and vibration10.Machine use ISO international standard CNCG code, while compatible with Japan Fanuc (FANUC) CNC system. Domesticmain stream programming, to facilitate the operator faster and easier to use thesystem.

11.The CNC system isGSK980TDC, With both horizontal and vertical structure. With 8.4-inch colorLCD, can control five feed axises (including Cs axis), 2 analog spindle, theminimum order unit of 0.1μm. PLC ladderdrawing showing, monitor, New function of soft keys, graphical interface design, the dialog box type operation, friendly man-machine interface 12.Version in Chinese,English, Spanish, Russian, Portuguese are available .With more function ofsystem time and warning log . 13.System programwith 40M, 384 program , editing function: index, modify, and delete 14.Program form: ISOCODE, support editing working including 15.Macro programming statements type, support the relative coordinates, the absolute coordinate andhybrid coordinate programming; 16.Systems support RS232 interface: parts program, two-way transmission parameters such as files,support for PLC program, the system software upgrade serial and USB interface:U disk file operations, U disk file processing, directly support the PLC program, USB system software upgrade.UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts