0

0 items

KSh0.00

No products in the cart.

Double column horizontal CNC band saw

1 in stock

Main features:

1. Extremely rigid dual column cast iron construction

2. PLC control for a fully automatic sawing process

3. Easy to use touch screen monitor for easy and quick recording of saw parameters

4. Hydraulic tool clamping included with standard equipment

5. The feed units linear measuring system ensures long term maximum accuracy

6. Feed of the torsion-proof sawframe is infinitely variable via a hydraulic throttle valve

7. Extra rigid, adjustable sawblade guide

8. Hydraulic workpiece clamping with clamping pressure control and bundle vise are included in the standard equipment

Add to Wishlist

Add to Wishlist

CNC Band saw GK260,GK320,GK400,GK500

1 in stock

Main features:

1. Full Automatic NC Sawapplicable to mass production and continuous cutting.

2. Touch screen type controlpanel, sawing parameters digital setting, presetting 5 groups of sawing data

3. PLC controller, completeautomatic sawing process

4. Double column structurevertical lifting high stability

5. Hydraulic pressure control thespeed of sawing stepless speed regulation

6. DRO control feeding length,high accuracy

Add to Wishlist

Add to Wishlist

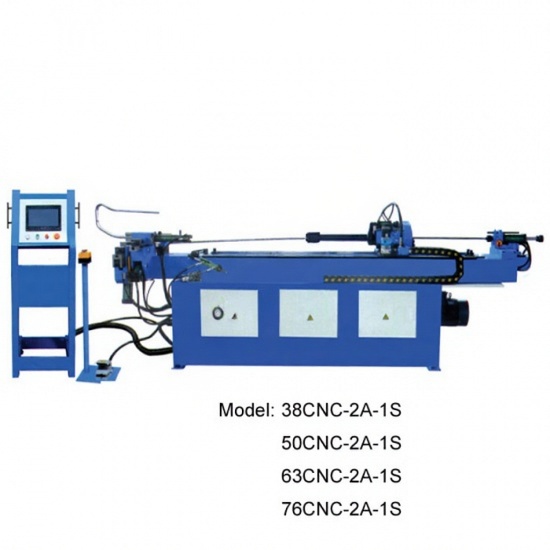

CNC Single Head Pipe Bending Machine 38;50;63;76CNC-2A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, hydraulic bending.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-4A-2S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating,servobending, servo moving die.

18.Double-layer mold.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-3A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, servobending.

Add to Wishlist

Add to Wishlist

Cylinder Block grinding machine 3M9735A×120,3M9735A×150,3M9735B× 120,3M9735B× 150

Available on backorder

Main features:

1. Spindle use high precision bearing with high machining precision.

2. Machine run smoothly and with small resistance.

3. Working table movement use frequency conversion stepless variable speed, suitable for machine different material parts.

Add to Wishlist

Add to Wishlist

Con-rod boring machine T8210D,T8216

Available on backorder

Add to Wishlist

Add to Wishlist

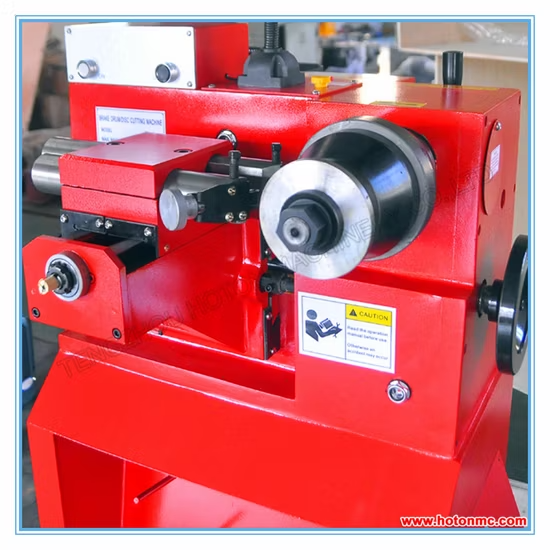

Brake drum Disc cutting machine T8445,T8465

Available on backorder

Main features:

1. The Brake drum/disc cutting machine is for repairing the brake drum or brake disc from mini car to heavy trucks.

2. It is a kindof infinitely veriable speed lathe.

3. It canfulfill the reparation of the brake drum disc and shoe of auto-mobiles frommini-car to medium heavy trucks.

4. The unusual feature of this equipment is its twin-spindle each other per pendicular structure.

5. The brake drum/shoe can be cut on the first spindle and the brake disc can be cut on thesecond spindle.

6. This equipment has higher rigidity, accurate workpiece positioning and is easy tooperate.

Add to Wishlist

Add to Wishlist

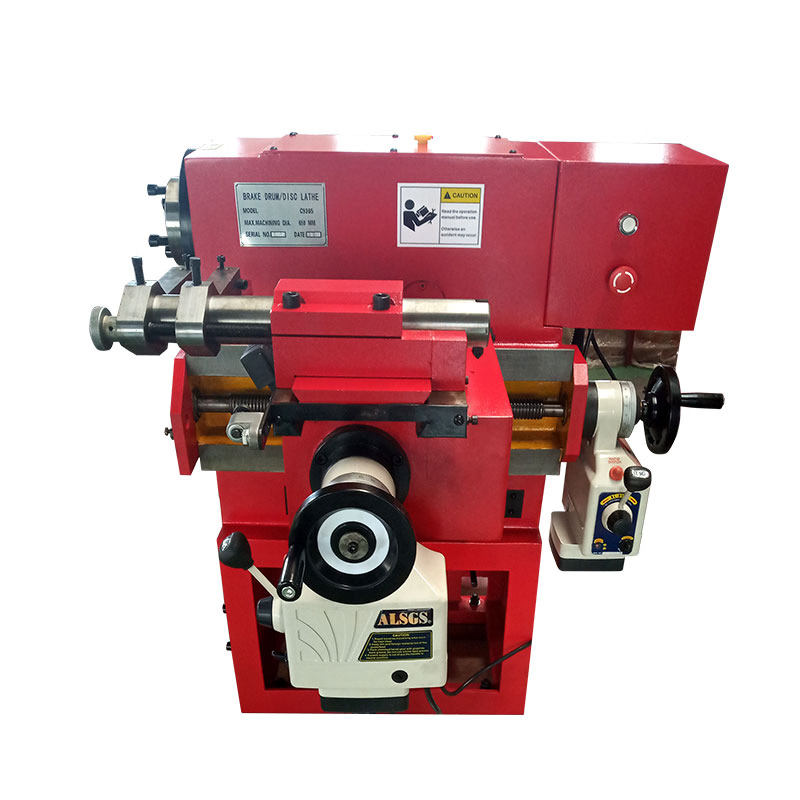

Brake drum lathe machine C9335

Available on backorder

Main features:

1. Quickly, accurately andefficiently to cutting rotor.

2. Fast and slow setting allowcutting rotor.

3. Quickly, accurately andefficiently to cutting drum.

4. Finitely adjustably settingallow cutting drum.

5. Three kinds of speed 70, 88,118 rpm to choose for spindle speed.

6. A convenient design allowsto quickly change from rotor to drum, with cross feed extension plate will beincrease the maximum rotor diameter to 22/588mm.

7. Position of stop make thelathe stop automatically after cutting.

8. Fully equipped with adapterpackage.

Add to Wishlist

Add to Wishlist

Cylinder Boring machine T806A,T807A,T808A,T8014A,T8016A

Available on backorder

Main features:

1. The machineis mainly used for reboring engine cylinders of automobiles motor cycles andtractors.

2. Reliableperformance, widely use, processing accuracy high productivity.

3. Easy andflexible operation.

4. Goodrigidity, amount of cutting.

Add to Wishlist

Add to Wishlist

Crank shaft grinding machine MQ8260A,MQ8260C

Available on backorder

Main features:

1. Three different work speeds areobtainable by making use of the belts in the headstock.

2. Cross chucks are used in theheadstock and tailstock.

3. Friction coupling is used inthe headstock transmission chain for its easy adjustment.

4. Table traverse is operatedeither by hand or by power.

5. Wheelhead rapid approach andwithdrawal is effected through hydraulic means.

6. The wheel spindle being of 80mmin diameter has good rigidity and strength.

7. Use is made of roller ways forwheelhead movement.

8. The bed ways and wheelhead arelubricated in an automatic cycle by means of the oil pump.

Add to Wishlist

Add to Wishlist

Cylinder Body Bushing Boring machine T8115Bx16,T8120x20,T8120Ax20

Available on backorder

Main features:

1. Model T8120x20 and T8115Bx16 cylinder body bushing boring machines are repairing machine tools with high efficiency and high precision.

2. Which were developed in our factory.

3. They can be used for boring master bushing and can bushing of engine & generator’s cylinder body in automobiles, tractors and ships etc.

if necessary, the fly wheel hub bore and bushing seat hole can be also finely bored.

4. In order to reduce auxiliary manhours and labour intensity and guarantee machining quality, accessories for centering, sectifying tool, measuring inner diameter,

boring rod bracket, tool holder to increase diameter, boring tool micro-adjuster and for distance tool sectifying device can be provided with the main machine.

Add to Wishlist

Add to Wishlist

Cylinder boring machine T8018A,T8018B

Available on backorder

Main features:

1. The cylinder boring machine is used for boring cylinder holes ofinternal combustion engine,and inner holes of cylinder sleeve of cars ortractors,and also for other machine element hole.It has high cost performance.

2. T8018A:Mechanical-electronic drive &spindle speed frequencechanged speed variation

3. T8018B:Mechanical drive

4. T8018C:Used for processing special heavy motor cylinders &Function of milling

Add to Wishlist

Add to Wishlist

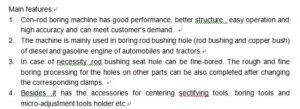

Main features:

1. The cylinder boring machine is used for boring cylinder holes of internal combustion engine, and inner holes of cylinder sleeve of cars or tractors, and also for other machine element hole. It has high cost performance.

2. T8018A:Mechanical-electronic drive &spindle speed frequency changed speed variation

3. T8018B:Mechanical drive

4. T8018C:Used for processing special heavy motor cylinders &Function of milling

Add to Wishlist

Add to Wishlist

Main features:

1. The machine is mainly used for boring and repairing the brake drum and plate for pick-up truck,car and mini car.

2. The machine use horizontal structure, low center of gravity and easy to clamping.

3. Use bearing outer ring of brake drum as the locating datum, use dabber and taper sleeve can easy to made clamping 、boring and repairing the brake drum come true.

4. The machine are good in rigidity,quick in cutter speed、high in efficiency.In general you only should turning one time, the machine can reach your accuracy requirement.

5. The machine is variable speed control without step,easy to operate, easy to repair, on the safe side.

Add to Wishlist

Add to Wishlist

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts