0

0 items

KSh0.00

No products in the cart.

Bull nose center BS2X60,BS3X76.2,BS4X160,BS5X200

Available on backorder

Main features:

1. Designed for large, hollow work pieces such as pipe, tube or other material that has alarge center hole.

2. Morse taper shank: MT2 to MT6.

3. Triple ball bearing design.

4. Shaft is made of alloy steel through heat treatment to Rc 60-62.

5. Dust and liquid proof seal for long service life.

Add to Wishlist

Add to Wishlist

Precision live center ML01,ML02,ML03,ML04,ML05,ML06

Available on backorder

Main Features:

1. Precise Accuracy: 0.005-0.010mm

2. Material is made of 65MN

3. Used for boring, milling,drlling, tapping,grinding and engraving operation etc

4. Improve the hardness and ensurance of thesurface

5. Cleaness better, Accuracy stable, Surface more smooth, Feel comfortable, Appearance nice

Add to Wishlist

Add to Wishlist

Precision light-duty live center LM-1,LM-2,LM-3,LM-4,LM-5,LM-6

Available on backorder

Main Features:

1.Design for medium duty lathe also suitable for CNC lathe.

2.Triple ball bearing design with extended spindle for high precision.

3.Shaft is made of alloy steel through heat treatment to Rc 60-62 to achieve high rigidity and durability.

4.Dust /water proof seal for long service life.

Add to Wishlist

Add to Wishlist

Precision heavy live center HM-1,HM-2,HM-3,HM-4,HM-5,HM-6

Available on backorder

Main Features:

1. material: body-40cr;center -t10

2. ground for high accuracy, accuracy: <=0.005mm

3. high speed 3000-5000rpm

4. precision high quality ball bearing center shaft, high hardness surface

Add to Wishlist

Add to Wishlist

Carbide medium-duty live center MD-1C,MD-2C,MD-3C,MD-4C,MD-5C

Available on backorder

Main Features:

1.Designed for medium speed medium load lathe.

2.Triple ball bearing design.

3.Carbide-tipped center point to achieve high abrasion resistance.

4.Shaft is made of alloy steel through heat treatment to Rc 60-62.

5.Dust and liquid proof seal for long service life.

Add to Wishlist

Add to Wishlist

SINO Digital read out

Available on backorder

Main features:

1. SDS6 digital readout employs the newest16bit SCM technology, can substitute all kinds of basic function and specialrequired function of SDS 2 series.

2. An all-purpose DRO the speed ofmeasurement is faster, and the control system is easier and smoother.

3. Each axis can supply 40 points ofnon-linear compensations.

4. We can get the compensated value throughthe double-frequency laser measurement machine, floor boring machine, floorboring machine, high accuracy boring machine, high accuracy grinding machine,lathe, EDM machine, milling machine and so on

5. And it supplies special function that tocontrol the processing speed of lathe.

6. When you process the wokpiece’sinside/outside in circle by lathe, the DRO can output relative simulativesignal on the basic of the change of the radius of the workpiece to control theprincipal axis’s transducer.

Add to Wishlist

Add to Wishlist

CNC internal grinding machine M2110CNC

Available on backorder

| Feature | |

| NC control with English display | |

| Belt driven spindle | |

| lighting system LED type, IP65 | |

| facility of auto lubrication syste for guide ways and screw | |

| coolant tank | |

| coolant flow from work spindle end facility | |

| backlight in operator panel | |

| cross roller guide ways for feeding axis | |

| machine should be suitable for tool rom work and production work | |

| roll dressing system for profril dressing |

Add to Wishlist

Add to Wishlist

UNIVERSAL CYLINDARCAL GRINDING MACHINE M1408X300

Available on backorder

Machine Feature

The machine is mainly used for grinding cylinder or cone surface of small axle, round set, needle valve, piston, etc. Tooling way can be top, three claws chuck, spring card head and special jig realized. Apply to process small parts such as meter , cars, mechanical and electrical, bearing, textile, ship, sewing machine, machine industry

The vertical movement of machine worktable have hydraulic and manual. Grinding wheel frame and head frame all can be turn. Hydraulic system uses good performance of the gear pump

The machine suitable for tools, maintenance and small and medium batch production workshop .

The top of machine is divided into 300 mm

Add to Wishlist

Add to Wishlist

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1420X800

Available on backorder

1.Table can be tilted for conical grinding operations and scale allows adjustment to desired position

2.Spindle stock can be swivelled 180° for inside grinding operations

3.Main spindle is mounted hydro-dynamically – oil film prevents contact between spindle and bearing

4.Longitudinal table guide and grinding spindle stock cross guide feature V- and flat guiding each

5.Strong reinforcements and generously designed walls make the machine base resistant to temperature fluctuations and deformations

6.Oil film between spindle and bearing reduces the vibrations to a minimum to achieve top results and high accuracy

7.Stepless feed adjustment with selective programmable stop at end of each table movement

8.Precisely adjusted spindle head and solid grinding spindle stock to achieve top processing results at various grinding operations

9.Precisely polished and manually finished guideways in x- and y-axis

10.Hydraulic or manual resetting of grinding spindle stock

11.Longitudinal movement of table is either manually by handwheel or automatically by hydraulic feed

12.Grinding spindle features bearings on both sides and adjustable sliding flat grids

Add to Wishlist

Add to Wishlist

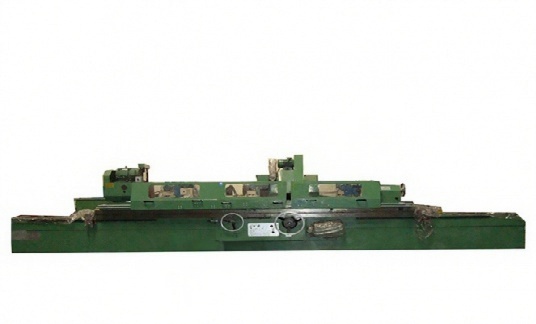

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1450

Available on backorder

1.The left and right guide rail adopts P-V structure, which is scraped by high precision manual, sothat the whole system products have high precision and high stability.

2.The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure

3.Classic control mechanism, simple, safe and reliable.

4.M1350, M1450, M1363 series worktable and grinding wheel guide rail adopts high stablehydrostatic guide rail, high rigid dynamic and static pressure spindle.

5.Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt tochuck grinding internal and external conical workpiece.

Add to Wishlist

Add to Wishlist

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1463

Available on backorder

| 1.The left and right guide rail adopts P-V structure, which is scraped by high precision manual, sothat the whole system products have high precision and high stability. 2.The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure 3.Classic control mechanism, simple, safe and reliable. 4.M1350, M1450, M1363 series worktable and grinding wheel guide rail adopts high stablehydrostatic guide rail, high rigid dynamic and static pressure spindle. 5.Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt tochuck grinding internal and external conical workpiece. |

Add to Wishlist

Add to Wishlist

CNC Cylindrical Grinding Machine

Available on backorder

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts