0

0 items

KSh0.00

No products in the cart.

BT shell mill arbors

Available on backorder

Main features:

- High quality elastic steel material with long use time.

- Type: A AD AD/B

- Shank of the BT Taper Shell Mill Arbors:BT30, BT40,BT50

- Suitable Facing Cutter:13mm-50mm

- The precision little than 0.01mm with balance 8000rpm. Higher precision also can be made by your demand.(G6.3/12000rpm, G2.5/20000rpm)

- Holder hardness:48-55HRC

- Suitable Pull Stub& Facing Cutter is also upon request.

Add to Wishlist

Add to Wishlist

BT drill chuck arbors

Available on backorder

Main features:

1.Made from carburized alloy steel, work surface hardness to HRC58~62.

2.Taper accurary≤ AT3, ensure well contact with spindle cone for high speed

running to protect the spindle.

3.Concentrictity and runout ≤0.005mm in high rpm.

Add to Wishlist

Add to Wishlist

BT End mill adapters

Available on backorder

Main features:

1.Made from carburized alloy steel, work surface hardness to HRC58~62.

2.Taper accurary≤ AT3, ensure well contact with spindle cone for high speed

running to protect the spindle.

3.Concentrictity and runout ≤0.005mm in high rpm.

Add to Wishlist

Add to Wishlist

BT morse taper with tang

Available on backorder

Main features:

1, The material: Allyed case hardened steel, black-finished and precisely grinded

2, The precision: 0.005mm

3, The hardness: 52-58HRC

4, Surface: black, sand-blasting

5, Taper tolerance: AT3

6, Dynamic balancing can be made G6.3/12000rpm, G2.5/25000rpm

Add to Wishlist

Add to Wishlist

BT milling chuck arbors

Available on backorder

Main features:

1.material:20CrMnTi

2.Comprehensive Accuracy:0.005mm

3.hardness:HRC56°-60°,carbon depth>0.8mm

4.Balanced G6.3/12000rpm,G2.5/20000rpm available

5.high temperature resistance.

Add to Wishlist

Add to Wishlist

HSK ER collect chuck

Available on backorder

Add to Wishlist

Add to Wishlist

HSK end mill holder

Available on backorder

Main features:

1.The material: Allyed case hardened steel, black-finished and precisely grinded

2.Taper tolerance: AT3 Standard

3.Hardness: 50-55HRC

4.Run out: 0.005mm

5.Coolant: AD, ADB, B type

6.Surface: blacken, sand blasting, plating

7.Dynamic balancing : G2.5/25000rpm

Add to Wishlist

Add to Wishlist

HSK shell end mill holder

Available on backorder

Main features:

1. Material: 20CrMnTi

2. Accuracy: 0.005mm

3. Hardness: HRC48-52

4.7:24 taper precision ≤AT3And part of the standard size are tested by standard inspection tools

5.Dynamic balance: we can do G2.5:15000rpm/20000rpm/25000rpm according to clients ‘demands

Add to Wishlist

Add to Wishlist

HSK combi-shell end mill holder

Available on backorder

Main features:

1. Material: 20CrMnTi

2. Accuracy: 0.005mm

3. Hardness: HRC48-52

4.7:24 taper precision ≤AT3And part of the standard size are tested by standard inspection tools

5.Dynamic balance: we can do G2.5:15000rpm/20000rpm/25000rpm according to clients ‘demands

Add to Wishlist

Add to Wishlist

Slotting head SLH-100,SLH-125

Available on backorder

Main features:

1. The slotting head can be widelyused for slotting, pressing, etc.

2. It can made teeth, inner hexspindle with attachment and special tooling.

3. The reciprocal movement is penalizedby a pair of 6 step triangle pulley worm and worm gear through an eccentricrlock.

4. Dial on the slotting head isused to adjust travel of slotting tube.

5. 100 and 125mm, two slotting strokes.

6. Cast iron body and Aluminum head cover.

Add to Wishlist

Add to Wishlist

New Slotting machine SLM-100,SLM-120

Available on backorder

Main features:

1. Heavy duty cast ironconstruction

2. Swivel head tilts left andright 90º

3. Dovetail vertical Z-Axis

4. 0-100mm machining stroke range

5. Strokes per minute 60-350 (6ranges)

6. 800 x 240mm table size

7. 230mm working table crosstravel

8. 560mm working tablelongitudinal travel

9. Safety chuck guard with micro

10. 14mm T-Slot on table

11. 370W/1/2hp, 240V motor

12. Includes steel fabricated stand

13. Suits 16mm diameter tooling

Add to Wishlist

Add to Wishlist

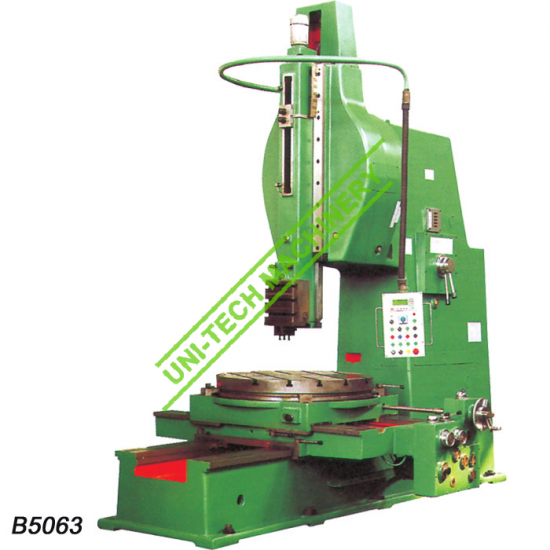

Slotting machine B5020D,B5032D,B5050A,B5063

Available on backorder

Main features:

1. This machine is used forslotting the flat and formed surface keyways, etc.

2. It is suitable for eithersingle piece of small batch production

3. The main transmission mechanismis used for converting the rotating motion of the crank gear into reciprocatingmotion of rain

4. The worktable Is designed forlongitudinal, cross and rotary feeding both automatically (only for D typemodel) and manually

5. The feed is stoppedautomatically, when the worktable is in case of trouble

Add to Wishlist

Add to Wishlist

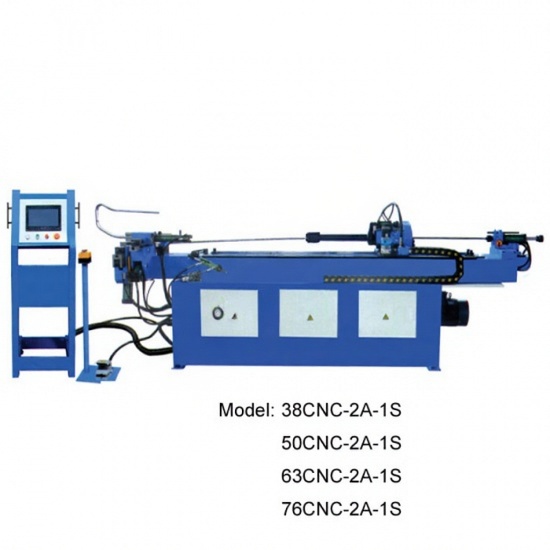

CNC Single Head Pipe Bending Machine 38;50;63;76CNC-2A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, hydraulic bending.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-4A-2S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating,servobending, servo moving die.

18.Double-layer mold.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-3A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, servobending.

Add to Wishlist

Add to Wishlist

Gap bed lathe machine GH1440K

Available on backorder

Main features:

1. Induction hardened, precision ground V-way bed.

2. D1-4 spindleis supported by high quality tapered roller bearing.

3. Hardened,precision ground gears in headstock.

4. High precision directly mounting chuck.

5. Carriage mounted spindle control lever.

6. Automatic feed and threading are fully interlocked.

7. Tailstock maybe offset for turning tapers.

8. One-piece casting iron base allows heavy cuts.

9. Tolerance test certificate, test flow chart included.

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts