0

0 items

KSh0.00

No products in the cart.

Round Column Drilling Machine D2,D3,D4

Available on backorder

Features:

1.Can be used drilling, core drilling, reaming, boring, tapping,spot-facing and chamfering etc.

2. Electrical system conforms with IEC standards.

3. The worktable can be rotated 360°or leaned +-45°and operated easily.

4.Change Speed with gears and operate easily.

5.8 speed steps with positive torque transmission - no belt slippage.

6.Easy rpm adjustment via two shift levers and 2-step main motor.

7.Heavy construction with thick-walled column.

8.Hand wheel for vertical feed of head with solid dual-clamp.

8.Depth scale with adjustable depth stop.

10.Height adjustable table and head allow the user to set the optimal work height.

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine Z5032A

Available on backorder

Features:

1.Gear driven system, 12 steps ofspindle speed.

2.Convenient loading andunloading tool device.

3.Automatic feed andtapping(Electromagnetic clutch),realize auto feed and tapping by putting anybutton on the feed handle.

4.CE or CSA or UL approved mainelectrical components.

5.Safety drill-guard withmicro-switch.

6.Worktable can be tilted ±45°and rotated ±180°round thecolumn.

7.Spindle box can be tilted ±45°and liftedup and down along the column.

8.Overload and short cutprotection

9.With coolant system

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine Z5040E,Z5040

Available on backorder

Main features:

1.Ideal for industrial workshop use

2.Geared head drilling machine with 4 morse taper spindle

3.Thread tapping with auto reverse

4.Automatic feed range (0.1, 0.2mm/rev)

5.18 drilling speeds from 50-1450rpm

6.Chuck guard with micro-switch

7.Drill ejector incorporated in machine

8.Coolant pump system with flexible hose

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine Z5030A,Z5035A,Z5040A,Z5050A

Available on backorder

Main Features:

1. New-designed,pleasing appearance,compact construction, wides speed change range,easy to operate.

2. Easy operation with its uniqueworkable,and both motor-drive and manual-operated lifting device.

3. The working table can be roteted180 and can be tited +45 and -45 also it is reliable and easy job can be done.

4. Equipped with coolant systemand tapping mechanism.

5. Equipped with short cut and overload protection, its electric, a system with powerful spindle-otormit designed according to IEC standard.

6. Characteristic protection device, small batch and mass production for drilling, counter boring, reaming,tapping, spot faing, ect.

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine Z5032Z,Z5040Z,Z5045Z

Available on backorder

Features:

1. With characteristic auto device for releasing tools, moreconvinent to change tools.

2. Worktable can be totated 3600 and also can be tilted 450 for easy operation.

3. Cyclic change ofspindle speed.

4. Headstock can beswiveled freely in per pendicular direction

5. Adjustable accurate depth setting withauto feed cut out for increased productivity

6. Both head and table are mounted on independentrack and pinions for ultimate positioning versatility

7. Coolant pump system with flexible hose

8. Work light mounted in convenient location

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine VD5032,VD5035,VD5040,VD5050

Available on backorder

Main Feature:

1.220-575V with 3PH collocation is available

2.All main parts are made with quality cast iron

3.Gear shift

4.Thin oil lubrication is available for drilling diameter 40mm and 50mm,grease lubrication is available for others.

5.Worktable could be rotated and could be inclined±45°.

6.Superior quality of gears with hardened and lapped gears of surface

7.Importable electrical components with CE,CSA and UL standard.

8.Supply tachometer,depth gauge and elevating motor of VD5040NB,VD5040NAVD5050NA,VD5050NB,it as special order.

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine Z5030V,Z5035V,Z5040V,Z5050V

Available on backorder

Main Feature:

1.3-phase with two- voltage for 220V~575V collocation

2.All main parts are made with quality cast iron

3.Single-speed motor, Germany original Lenze transducer spindle stepless timing for Z series.

4.Strength spindle, large diameter column,Trochoid lubrication pump

5.Worktable could be rotated and could be inclined ±45°

6.Motor driven lifting of worktable.

7.Digital readout for the display of speed and cutting depth

8.Micro feed is available.

9.Coolant System and fender device

10.Supply accessories Φ6~Φ16mm collet, handle of millingcutter,cross worktable,handle of collet, nut for t-slot, inner haxagonbolt

11.Importable electrical components with CE,CSA and UL standard

12.The model with A is electromagnetism clutch transmission feed, with B is mechanical feed.

Add to Wishlist

Add to Wishlist

Round Column Drilling Machine VD4025,VD4035NA

Available on backorder

Main features:

1.Leveron gear head allows easy speed adjustment

2.Adjustable drill depth stop includes scale

3.Absolute concentricity ≤0,02 mm, measured at spindle

4.Left and right rotation allows thread cutting

5.Grey,cast-iron table includes T-slots and coolant grooves

6.Automatic tool release device and LED working light come standard

7.High concentricity - spindle runs on high-quality bearings

8.Hardened,polished gear wheels ensure smooth run

9. Solid, polished steel column is designed for constant use.

Add to Wishlist

Add to Wishlist

Universal tool milling machine UM300A,UM400A

Available on backorder

Main features:

1. Hand wheel guarantees simpleand precise feed settings

2. Complete with manual, automaticand rapid feed in all three axis

3. Central lubrication in guide ways comes standard

4. Clear design of speed and feed controls

5. Vertical clamping area with 5T-slots allows clamping of work table, universal tilting table and oversize work pieces

6. Optimal adjustments of spindle speed and feed allow for economic machining of various materials

7. Solid grey cast-iron machine base guarantees precision and minimizes vibrations

8. Ultimate machine for tool andmould construction, training, industry, model making and proto typing etc.

9. Hardened and polished guidewaysguarantee top accuracy

10. Tiltable vertical milling headwith spindle adjustment and three automatic drill feeds

Add to Wishlist

Add to Wishlist

CNC internal grinding machine M2110CNC

Available on backorder

| Feature | |

| NC control with English display | |

| Belt driven spindle | |

| lighting system LED type, IP65 | |

| facility of auto lubrication syste for guide ways and screw | |

| coolant tank | |

| coolant flow from work spindle end facility | |

| backlight in operator panel | |

| cross roller guide ways for feeding axis | |

| machine should be suitable for tool rom work and production work | |

| roll dressing system for profril dressing |

Add to Wishlist

Add to Wishlist

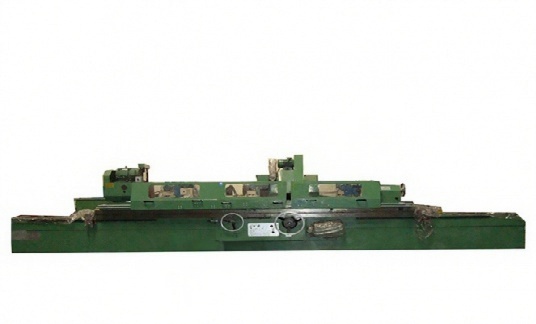

UNIVERSAL CYLINDARCAL GRINDING MACHINE M1408X300

Available on backorder

Machine Feature

The machine is mainly used for grinding cylinder or cone surface of small axle, round set, needle valve, piston, etc. Tooling way can be top, three claws chuck, spring card head and special jig realized. Apply to process small parts such as meter , cars, mechanical and electrical, bearing, textile, ship, sewing machine, machine industry

The vertical movement of machine worktable have hydraulic and manual. Grinding wheel frame and head frame all can be turn. Hydraulic system uses good performance of the gear pump

The machine suitable for tools, maintenance and small and medium batch production workshop .

The top of machine is divided into 300 mm

Add to Wishlist

Add to Wishlist

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1420X800

Available on backorder

1.Table can be tilted for conical grinding operations and scale allows adjustment to desired position

2.Spindle stock can be swivelled 180° for inside grinding operations

3.Main spindle is mounted hydro-dynamically – oil film prevents contact between spindle and bearing

4.Longitudinal table guide and grinding spindle stock cross guide feature V- and flat guiding each

5.Strong reinforcements and generously designed walls make the machine base resistant to temperature fluctuations and deformations

6.Oil film between spindle and bearing reduces the vibrations to a minimum to achieve top results and high accuracy

7.Stepless feed adjustment with selective programmable stop at end of each table movement

8.Precisely adjusted spindle head and solid grinding spindle stock to achieve top processing results at various grinding operations

9.Precisely polished and manually finished guideways in x- and y-axis

10.Hydraulic or manual resetting of grinding spindle stock

11.Longitudinal movement of table is either manually by handwheel or automatically by hydraulic feed

12.Grinding spindle features bearings on both sides and adjustable sliding flat grids

Add to Wishlist

Add to Wishlist

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1450

Available on backorder

1.The left and right guide rail adopts P-V structure, which is scraped by high precision manual, sothat the whole system products have high precision and high stability.

2.The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure

3.Classic control mechanism, simple, safe and reliable.

4.M1350, M1450, M1363 series worktable and grinding wheel guide rail adopts high stablehydrostatic guide rail, high rigid dynamic and static pressure spindle.

5.Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt tochuck grinding internal and external conical workpiece.

Add to Wishlist

Add to Wishlist

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1463

Available on backorder

| 1.The left and right guide rail adopts P-V structure, which is scraped by high precision manual, sothat the whole system products have high precision and high stability. 2.The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure 3.Classic control mechanism, simple, safe and reliable. 4.M1350, M1450, M1363 series worktable and grinding wheel guide rail adopts high stablehydrostatic guide rail, high rigid dynamic and static pressure spindle. 5.Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt tochuck grinding internal and external conical workpiece. |

Add to Wishlist

Add to Wishlist

CNC Cylindrical Grinding Machine

Available on backorder

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts