0

0 items

KSh0.00

No products in the cart.

DC inverter MMA welder

Available on backorder

Main features:

1. Minimizing, lightness, highquality and energy-saving.

2. Good arc-starting and arcforce, it can resist disturbing stable arc and little spatter.

3. High welding quality, deeppenetration and strong strength.

4. Auto protection of over-voltageand over-current.

5. Be able to work continuously,it can balance automatically when voltage is waving.

6. Suit for welding all kinds ofbasic welding rod.

7. Be able to weld cellulose rod.

Add to Wishlist

Add to Wishlist

AC arc welder BX1,BX6

Available on backorder

Main features:

1. Single phase moving core typeand forced air cooling structure.

2. Suitable for welding ferrousmetal workpiece with general AC electrode.

3. Stable arc, less spatter anddeep penetration can ensure welding quality well.

4. Simple structure, high efficiency,easy to operate and maintenance.

Add to Wishlist

Add to Wishlist

DC inverter TIG welder

Available on backorder

Main Features:

1. Advanced inverter technology, high working frequency, compact size andweight, easy to carry

2. Stable and reliable welding current.

3. Low No-load loss, low energy consumption

4. Applicable for welding of ferrous-metals, medium carbon steel and alloysteel,etc.

Add to Wishlist

Add to Wishlist

Welding machine MIG

Available on backorder

Main features:

1. Single-phase,portable,fan-cooledwire welding machine for flux(no gas) and MIG/MAG(gas)welding

2. With thermal protection, complete with MIG welding accessories.

3. The kit for welding different types of materials such as steel,stainless steel.

4. Steel and aluminum is available on request.

Add to Wishlist

Add to Wishlist

Spot welder DN series Spot welder DN series

Available on backorder

Main features:

1. Low power consumption of maintransformer

2. Water-cooling structure.

3. Easy operation and maintenancewith pedal-level type spring-press structure.

4. Adjustable welding time, easywelding repeated.

5. Suitable for low carbon steel,wire, stainless steel plate etc.

6. Widely used for welding mediumand low carbon steel plates, stainless steel material in industrial production

Add to Wishlist

Add to Wishlist

Plasma cutting CUT series

Available on backorder

Main features:

1. Cutting capacity increased 1.8times higher in cutting speed compare with flame cutter

2. Thick metal plate can be cuteasily and quickly.

3. Suitable for cutting stainlesssteel, copper, iron and aluminium metal etc.

4. Simple operation, smooth cuttingsurface.

5. Hf untouched Arc-startingcutting (70,100,120)

6. Hf touched Arc-staring cutting(30,40,60).

Add to Wishlist

Add to Wishlist

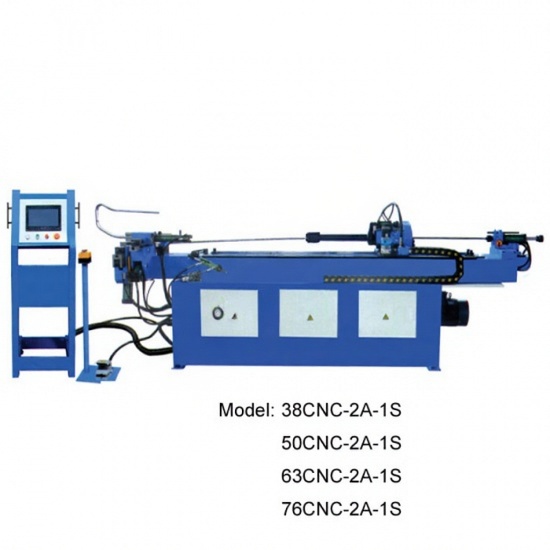

CNC Single Head Pipe Bending Machine 38;50;63;76CNC-2A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, hydraulic bending.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-4A-2S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating,servobending, servo moving die.

18.Double-layer mold.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-3A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, servobending.

Add to Wishlist

Add to Wishlist

CNC Hydraulic shearing machine QC12K

Available on backorder

Features:

1.The machine is fitted with CNC controller special for shearing machines.

2.The position of rear stopper is displayed in real-time manner.

3.Multi-stepprogramming function is available and the rear stopper is able for automatic operationand continuous positioning, to achieve an automatic adjustment for position of rear stopper.

4.It is provided with counting function for shearing, to display the shearingnumbers in a real-time manner, able for power-failure memory of position of rearstopper, procedures, and parameters.

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts