0

0 items

KSh0.00

No products in the cart.

Bead bending machine RM08

Available on backorder

Features:

1. The Rotary machine, the same as the ordinary beading machine,is used for blank pressing, arc pressing and so on for various plates.

2. Rotary machine includes 6 sets standard rollers

3. can be forming different shapes to meet various processing demands.

4. Adjustable roll pressure by means of top mounted hand crank.

5. Can be used in both forward and reverse

6. Can be operated smooth, fast and precisely.

7. Table mount with clamp is standard

Add to Wishlist

Add to Wishlist

Bead bending machine TB-12

Available on backorder

Features:

1. The Bead bending machine makes swaged plate, connection andso on of circular pipes, which refer to crushing the thin plates into the ribsin certain

shapes.

2. The rigidity of the plates, pipes or metal components isstrengthened.

3. Heavy and solid cast iron construction

4. Special steel adjustable bottom spindle

5. Complete with stand 4 sets standard rollers

Add to Wishlist

Add to Wishlist

Bead bending machine ETB-12

Available on backorder

Features:

1. The Bead bending machine makes swaged plate, connection andso on of circular pipes, which refer to crushing the thin plates into the ribsin certain shapes.

2. The rigidity of the plates, pipes or metal components isstrengthened.

3. Heavy and solid cast iron construction

4. Special steel adjustable bottom spindle

5. Complete with stand 4 sets standard rollers

6. Self-braking motor with subframe (E-type model ETB-12)

7. Easy to operate with foot pedal control (E-type model ETB-12)

Add to Wishlist

Add to Wishlist

Bead bending machine ETB-25,40

Available on backorder

Features:

1. The Bead bending machinemakes swaged plate, connection and so on of circular pipes, which refer tocrushing the thin plates into the ribs in certain shapes.

2. The rigidity of the plates,pipes or metal components is strengthened.

3. Steel welded constructionframe

4. Adjustable idle roller

5. Steel shaft with bronzebushings

6. Reduction motor with brakesystem

7. Movement of rollers withfoot pedal

8. Complete with stand

9. 4 sets standard rollers

Add to Wishlist

Add to Wishlist

Bead bending machine RM-A,RM-B

Available on backorder

Features:

1. Hardened steel rollers

2. Head rotates 360 degree

3. Can bench mounded with “EZ Edge Finder”

4. Main technical parameter

Add to Wishlist

Add to Wishlist

M7130A,M7130B,M7130C,M7132

Available on backorder

Wheel Head Moving Surface Grinding Machine M7130A,M7130B,M7130C,M7132 |

| Main features: 1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting 2.Grind wheel head spindle front end adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity,specially for heavy-duty cutting. 3.Transmission: Worktable adopts one flat andone V guide ways, driven by hydraulic with smooth movement. 4.Grinding wheel adopts two sets of guideway, one is flat guide way for up/down moving. 5.Another set is swallow tail guide way forback-forward movements, with manual feeding or Auto-feedingby hydraulic cylinder. 6.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank. The temperature of the oil tank raises little so the thermal distortion of the machine is small. 7. Full lubrication system ensuring all guide ways smooth moving. |

Add to Wishlist

Add to Wishlist

M7140A,M7130A

Available on backorder

Wheel Head Moving Surface Grinding Machine M7140A,M7130A |

| Main features: 1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting 2.Grind wheel head spindle frontend adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity, specially for heavy-duty cutting. 3.Transmission: Worktable adopts one flat and one V guide ways, driven by hydraulic with smooth movement. 4.Grinding wheel adopts two setsof guide way, one is flat guide way for up/down moving. 5.Another set isswallow tail guide way for back-forward movements, with manual feeding or Auto-feeding byhydraulic cylinder. 6.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank. The temperature of the oil tank raises little so the thermal distortion of the machine is small. 7.Full lubrication system ensuring all guide ways smooth moving. |

Add to Wishlist

Add to Wishlist

Wheel Head Moving Surface Grinding Machine M7180 |

| Main features: 1. BallLead screw used for forward and back feeding., also worktable 2. Table with Turcite “B” for longer time life. 3. Bigbore oil cylinder adopted for better processing ability. 4. Wheel Head moving type. 5.Individual hydraulic station design. 6. Coolant and complete lubrication available |

Add to Wishlist

Add to Wishlist

M7150A,M7163

Available on backorder

Wheel Head Moving Surface Grinding Machine M7150A,M7163 |

| Main features: 1. Ball Lead screw used for forward and back feeding.,also worktable 2. Table with Turcite “B” for longer time life. 3. Big bore oil cylinder adopted for better processingability. 4. Wheel Head moving type. 5. Individual hydraulic station design. 6. Coolant and complete lubricationavailable |

Add to Wishlist

Add to Wishlist

Dial Test indicators DTI411-0.8A

Available on backorder

Features

1.High quality brass main body High resistance to magnetism

2.Jeweled , vibration proof, durbi

3.Pivot ball bearing

4.Carbide, jewel ball or steel

5.Three dovetails

Add to Wishlist

Add to Wishlist

Micrometer dial indicator MDI-A

Available on backorder

Features

Steel Body

Jeweled

Anti-dirty cap

With dial lock screw

Plastic flat back is valid for standard

Add to Wishlist

Add to Wishlist

Micrometer dial indicator IDI-A

Available on backorder

Features

1.Aluminium body

2.Lifting screw with cushion rubber

3.External tolerance indicator

4.With dial lock screw

5.Metal lug back is valid for standard

Add to Wishlist

Add to Wishlist

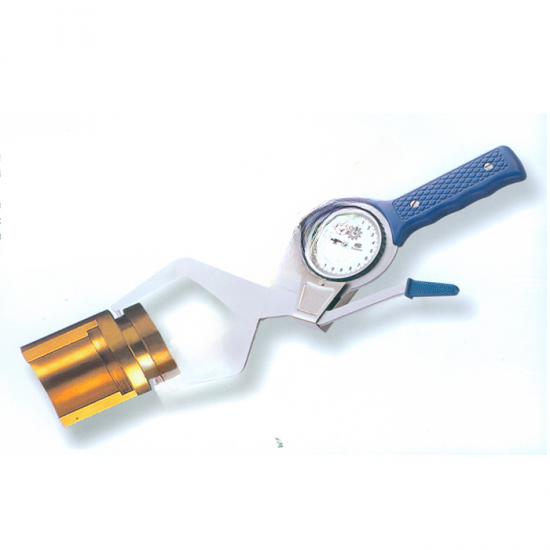

Metric inside dial cliper gauges

Available on backorder

Features

1. Using in Holes of the work piece, inside diameter, ring groove bottom diameter.

2. With gauge easy to read

3. Material using spring stainless steel.

4.The shock proof dial caliper gauges are available.

Add to Wishlist

Add to Wishlist

CNC Lathe Machine UTK36

Available on backorder

Features

1. Using the precision of hole type spindle structure, smooth operation, the infinite speed, high speed, especially suitable for non-ferrous metal processing.

2. Using the precision bearing spindle bearing, high precision, long service life.

3. The lathe bed guide rail by the medium frequency quenching and precision grinding, saddle guide model, and good accuracy stable.

4. Smooth chip removal, work piece clamping and convenient.

5. Equipped with vertical electric tool postfor 4 station, high positioning accuracy, choose knife time is short, stablerunning and reliable.

6. Easy separate cooling water tank cleaningmaintenance.

7.The control console can be mounted at left end or right end according to your operating habits.

8.The machine is applicable to batch production of multi-specification work, especially precision work in complex contours.

Add to Wishlist

Add to Wishlist

Mini CNC Lathe Machine UTCK300

Available on backorder

Features

1.Spindle Bore Dia. 48 mm.(UTCK300), Dia. 63mm (UTCK360)

2.Electric Hand wheel

3.Encoder

4.Auto-coolant

5.Auto-lubrication forlead screw and Guide way.

6.Manual 3-jaw chuck 6”

7.Manual Tail stock

8.4—Position Turret

9.GSK 980TD b system

10.Cabinet braker

11.Full protection

12.Inverter spindle

13.Heat exchanger

14.USB Port Face

Add to Wishlist

Add to Wishlist

Mini CNC Lathe Machine UTCK400

Available on backorder

Features

1.OnePiece cast iron stand with High rigidity

2.Linearguide way imported with fast movement and high accuracy.

3.Morechoice for clamping and tool post

4.More convenience chip remove

5.Centrallubrication

6.Full-enclosedcover with perfect water-proof.

7.Suitablefor big size plate and shaft processing.

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts