0

0 items

KSh0.00

No products in the cart.

Bull nose center BS2X60,BS3X76.2,BS4X160,BS5X200

Available on backorder

Main features:

1. Designed for large, hollow work pieces such as pipe, tube or other material that has alarge center hole.

2. Morse taper shank: MT2 to MT6.

3. Triple ball bearing design.

4. Shaft is made of alloy steel through heat treatment to Rc 60-62.

5. Dust and liquid proof seal for long service life.

Add to Wishlist

Add to Wishlist

Precision live center ML01,ML02,ML03,ML04,ML05,ML06

Available on backorder

Main Features:

1. Precise Accuracy: 0.005-0.010mm

2. Material is made of 65MN

3. Used for boring, milling,drlling, tapping,grinding and engraving operation etc

4. Improve the hardness and ensurance of thesurface

5. Cleaness better, Accuracy stable, Surface more smooth, Feel comfortable, Appearance nice

Add to Wishlist

Add to Wishlist

Precision light-duty live center LM-1,LM-2,LM-3,LM-4,LM-5,LM-6

Available on backorder

Main Features:

1.Design for medium duty lathe also suitable for CNC lathe.

2.Triple ball bearing design with extended spindle for high precision.

3.Shaft is made of alloy steel through heat treatment to Rc 60-62 to achieve high rigidity and durability.

4.Dust /water proof seal for long service life.

Add to Wishlist

Add to Wishlist

Precision heavy live center HM-1,HM-2,HM-3,HM-4,HM-5,HM-6

Available on backorder

Main Features:

1. material: body-40cr;center -t10

2. ground for high accuracy, accuracy: <=0.005mm

3. high speed 3000-5000rpm

4. precision high quality ball bearing center shaft, high hardness surface

Add to Wishlist

Add to Wishlist

Carbide medium-duty live center MD-1C,MD-2C,MD-3C,MD-4C,MD-5C

Available on backorder

Main Features:

1.Designed for medium speed medium load lathe.

2.Triple ball bearing design.

3.Carbide-tipped center point to achieve high abrasion resistance.

4.Shaft is made of alloy steel through heat treatment to Rc 60-62.

5.Dust and liquid proof seal for long service life.

Add to Wishlist

Add to Wishlist

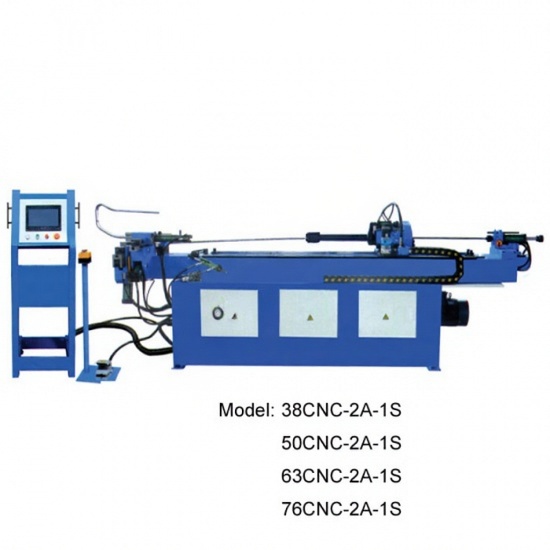

CNC Single Head Pipe Bending Machine 38;50;63;76CNC-2A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, hydraulic bending.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-4A-2S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating,servobending, servo moving die.

18.Double-layer mold.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-3A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, servobending.

Add to Wishlist

Add to Wishlist

Manual Surface Grinding Machine MJ7115 |

| Features: 1. Surface grinding is designed to grind various horizontal and vertical surfaces of the workpieces and endfaces of the grinding wheel. 2. It can also grind various contoured workpieces with shaped wheel or crafts manship apparatus. 3. Integrated grinding head of high quality, high rigidity and accuracy. 4. Small size, light weight,easy operation & maintenance. 5. Centralized lubrication for oil pump. 6. Super slide table 7.Enclosed cabinet style stand 8.Swarf guard 9.One shot lubrication 10.Diamond wheel dresser with holder 11.Tool Box 12.Wheel balancing kit 13.Single phase 3450 RPM motor |

Add to Wishlist

Add to Wishlist

M618A,M820

Available on backorder

Manual Surface Grinding Machine M618A,M820 |

| Mainfeatures: 1.Quality castings and Precision ball bearing supporting thespindle 2.Coolant system with nozzle and flow control valve 3.Cast iron machine body and stand for maximum rigidity andsmooth operation 4.The machine can grind all kinds of surfaces or grind complex surfaces by dressing of grinding wheel. 5.The machineis suitable for grinding without auto feed and is installed with permanentmagnetic chuck or electromagnetic chuck according to customer’s requirement. 6.Vertical dial graduations 0.01mm,Cross travel graduations 0.02mm 7.Manual one shot lubrication pump 8.Wheel balancing stand and arbor 9.Halogen work light |

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts