0

0 items

KSh0.00

No products in the cart.

Main features:

1. Double column structure vertical lifting high stability

2. High efficiency, high precision save material saving energy

3. The hydraulic pressure controls the speed of saw stepless speed regulation

4. The camp of workpieces and hydraulic, control easily

5. Can made 3 hydraulic tension saw blades per request

Add to Wishlist

Add to Wishlist

Main features:

1. Double column structure vertical lifting high stability

2. High efficiency, high precision save material saving energy

3. The hydraulic pressure controls the speed of saw stepless speed regulation

4. The camp of workpieces and hydraulic, control easily

5. Can made 3 hydraulic tension saw blades per request

Add to Wishlist

Add to Wishlist

Double column horizontal band saw GH4220

1 in stock

Main features:

1. Saw frame travels across soliddual-column guides

2. Rigid, adjustable saw bladeguides prevent lateral escape of the saw blade and ensure maximum angularaccuracy

3. Ideally positioned controlpanel within comfortable reach on top of the saw frame

4. At the end of each sawingcycle, the saw blade frame will automatically return to the home position

5. Throttle valve allowsinfinitely variable saw frame feed

6. Two cutting speeds for a widespectrum of materials and workpiece diameters

7. Manually adjustable workpiececlamping and linear stop

8. Coolant system

Add to Wishlist

Add to Wishlist

Main features:

1. With hydraulic system tocontrol the cutting speed, variable speed

2. Useful guide system, to keelthe blade can be use with long time

3. Double column structure, steadyoperations

4. Steady cutting, high accuracy

5. Manual clamping workpiece, easyoperations

Add to Wishlist

Add to Wishlist

Main features:

1. Double-column horizontal bandsawing machine, mainly used for all kinds of sawing large materials, have highefficiency high precision save material saving energy etc.

2. Double column structurevertical lifting high stability

3. Adopts linear guide rail andhigh precision

4. Double oil cylinder control, tooperate smoothly

5. The hydraulic pressurecontronls the speed of saw stepless speed regulation

6. The camp of workpieces and hydraulic, control easily

7. Electric automatic feed

Add to Wishlist

Add to Wishlist

Main features:

1. Double column structure, withbig dia.column and inside with auto lubrication bearings, insure verticallifting high stability

2. Blade with guide function andbearing guide function, enlarge the blade use life

3. High quality worm gear speedreduction box, with high accuracy and low noise,vibration.

4. Hydraulic system made sure thelifting speed stable and gurantee the cutting accuracy

Add to Wishlist

Add to Wishlist

Main features:

1. Gantry structure, high accuracy linear guide way, save blade, insurance guide accuracy.

2. With big dia.column and inside with auto lubrication bearings, insure vertical lifting high stability

3. Blade with guide function and bearing guide function, enlarge the blade use life

4. High quality worm gear speed reduction box, with high accuracy and low noise,vibration.

5. Hydraulic system made sure the lifting speed stable and gurantee the cutting accuracy

6. Laser tool, make sure the work piece accuracy and fast positioning

Add to Wishlist

Add to Wishlist

Main features:

1. Unique sealing Maintenancereduction system with worm gear, insurance forever-lubrication, enlarge the uselife of saw blade

2. Hydraulic lifting oil and highstable spring, variable, work smoothy

3. Blade cover protection, ignorethe breakage of saw blade

4. Adjustable blade guide system

5. Many kinds of electricprotection function and with open sotp

6. Different swivel cutting, forsection steel, round steel pipe, square steel pipe

7. Vice can be movable, benefitfor clamping workpiece

Add to Wishlist

Add to Wishlist

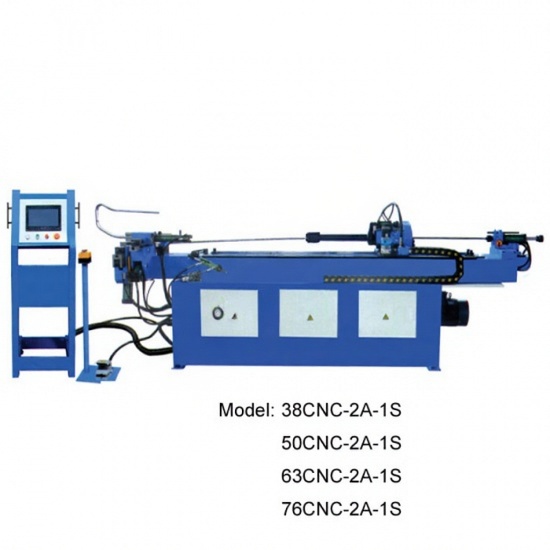

CNC Single Head Pipe Bending Machine 38;50;63;76CNC-2A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, hydraulic bending.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-4A-2S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating,servobending, servo moving die.

18.Double-layer mold.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-3A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, servobending.

Add to Wishlist

Add to Wishlist

CNC Lathe Machine UTK36

Available on backorder

Features

1. Using the precision of hole type spindle structure, smooth operation, the infinite speed, high speed, especially suitable for non-ferrous metal processing.

2. Using the precision bearing spindle bearing, high precision, long service life.

3. The lathe bed guide rail by the medium frequency quenching and precision grinding, saddle guide model, and good accuracy stable.

4. Smooth chip removal, work piece clamping and convenient.

5. Equipped with vertical electric tool postfor 4 station, high positioning accuracy, choose knife time is short, stablerunning and reliable.

6. Easy separate cooling water tank cleaningmaintenance.

7.The control console can be mounted at left end or right end according to your operating habits.

8.The machine is applicable to batch production of multi-specification work, especially precision work in complex contours.

Add to Wishlist

Add to Wishlist

Mini CNC Lathe Machine UTCK300

Available on backorder

Features

1.Spindle Bore Dia. 48 mm.(UTCK300), Dia. 63mm (UTCK360)

2.Electric Hand wheel

3.Encoder

4.Auto-coolant

5.Auto-lubrication forlead screw and Guide way.

6.Manual 3-jaw chuck 6”

7.Manual Tail stock

8.4—Position Turret

9.GSK 980TD b system

10.Cabinet braker

11.Full protection

12.Inverter spindle

13.Heat exchanger

14.USB Port Face

Add to Wishlist

Add to Wishlist

Mini CNC Lathe Machine UTCK400

Available on backorder

Features

1.OnePiece cast iron stand with High rigidity

2.Linearguide way imported with fast movement and high accuracy.

3.Morechoice for clamping and tool post

4.More convenience chip remove

5.Centrallubrication

6.Full-enclosedcover with perfect water-proof.

7.Suitablefor big size plate and shaft processing.

Add to Wishlist

Add to Wishlist

CNC Lathe machine CK6152E

Available on backorder

Main features:

This machine is suitable to process the middle and large size workpiece in steel, cast iron, non-ferrous metal material. With the feature of big power and higher rigidity, this machine is applied to heavy-cut the inner circle, ex-circle, end surface and thread in both metric and English system, and could drill and bore holes.

1. Bed width440mm

2.higherstability one-piece machine cast iron stand .

3.3 gearspindle speed, stepless in gear

4.higherrigidity pedestal

5.wider layerboard

6.integratedautomatic lubrication system

7.onepiece cast iron stand for convenience chip conveyor and more rigidity.

8. Spindle boredia. 90mm

Add to Wishlist

Add to Wishlist

CNC Lathe machine TCK6340S

Available on backorder

Main Features:

This machine is applicable to automobile, motorcycle, electronics, aerospace, military, oil and other industry. It could turn the conical surface, circular arc surface, end face of the rotary parts, could also turn various metric and

inch threads etc, with higher efficiency and higher precision in bulk.

1.45 degrees slant bed CNC lathe

2.Higher accuracy Taiwan linear guide

3.Chip conveying capacity is large and convenient, customer could choose

4.Chip conveying in the front or in the back

5. X, Z direction servo motorthrough high torque low inertia flexible coupling directly connected with thescrew, screw supporting the use of pre-stretching structure

6.Gang type tool post

7. high-speed high-precision high-rigidityshell-type spindle unit, servo spindle motor, can achieve higher spindlespeeds.

8. Use advancedcentralized lubrication system uses

9. machine with full protection design,waterproof debrisreliable, easy maintenance.

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts