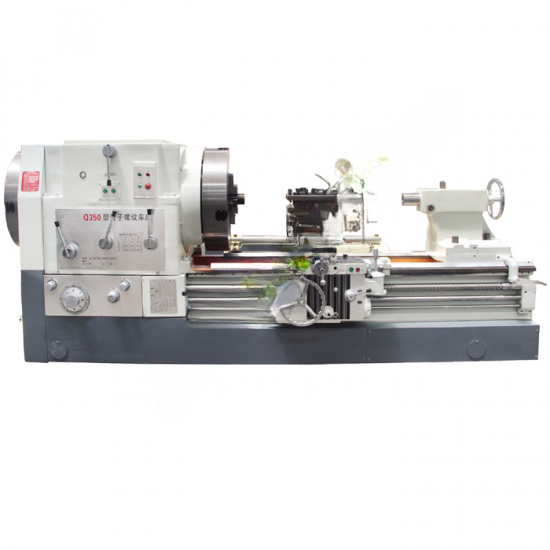

Pipe threading lathe machine QK1319

Features:

1.mainly used for processinginner andouter pipe thread (including metric thread and inch thread).

2.It can undertake variousturning workssuch as turning inner and outer cylindrical surface, conicalsurface and otherrevolution and end surfaceas general CNC lathes.

3.It used in various machineryprocessing,petroleum exploiting and delivering, mining, vehicle and ship parts

4.The spindle bore is very large and set up double chucks both front and ack and you canchoose electric chucks as you like.

5.The surface of the slide railof the bedis treated by the super audio quench, which can be endurable andwear-resisting.The slide rail f saddle is treated by wear-resisting layercoated, to avoid thecrawling.

6.There are two types of speedchange:Manual and step less.

7.Set up self lubricationsystem, and easyto maintain

Description

| ITEMS | QK1322×1500mm | QK1319×1500mm | QK1319×3000mm |

| Swing over bed (mm) | Φ630 | ||

| Swing over carriage (mm) | Φ340 | ||

| Range of processing pipe thread (mm) | Φ50-220 | Φ50-193 | Φ50-193 |

| Distance between centers (mm) | 1500 | ||

| Width of bed (mm) | 550 | ||

| Spindle bore (mm) | Φ225 | Φ200 | Φ200 |

| Main motor power (kw) | 7.5 | 11 | 11 |

| Step and range of spindle speed (r/min) | 2steps 30-80/80-300 | ||

| Feed volume and screw pitch (mm) | 0.001-40 | ||

| Max stroke/traverse of X (mm) | X: 520 | ||

| Max stroke/traverse of Z (mm) | Z: 1250 | Z: 2750 | |

| Rapid moving speed X/Z (r/min) | 4000 | ||

| X servo motor power (kw/Nm) | X:1.5/10 | X: 1.4/10.5 | X: 1.4/10.5 |

| Z servo motor power (kw/Nm) | Z:2.3/15 | Z: 2.5/20 | Z: 2.5/20 |

| Positioning accuracy (mm) | 0.02 | ||

| Repositioning accuracy (mm) | 0.01 | ||

| Diameter and taper of tailstock quill (mm/mores) | Φ100/m5 | ||

| Tailstock quill travel (mm) | 250 | ||

| Tailstock cross travel (mm) | ±15 | ||

| CNC system | GSK980TC3 | Fanuc Oi Mate | Fanuc Oi Mate |

| Size of tool section (mm) | 32×32 | ||

| Overall dimensions (L×W×H) (mm) | 3657×1360×1555 | 5157×1360×1555 | |

| Net Weight (kg) | 4200 | 5050 | |