KSh0.00

Oil Country Lathe Machine

Pipe threading lathe machine Q1322

Main Features:

1. All parts processed in precision to ensure lathe work in good performance.

2. The ultrasonic frequency quenched guide-ways have good wear-resistance.

3. The gears have been quenched and ground by grinding machine.

4. The spindle adopts two-supporting structure and runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made of high quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safety devices such as braking system, emergency power-off switch and overload protection system.

Pipe threading lathe machine Q1327

Main Features:

1. All parts processed in precision to ensurelathe work in good performance.

2. The ultrasonic frequency quenched guide-wayshave good wear-resistance.

3. The gears have been quenched and ground bygrinding machine.

4. The spindle adopts two-supporting structureand runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made ofhigh quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safetydevices such as braking system, emergency power-off switch and overloadprotection system.

Pipe threading lathe machine Q245

Main Features:

1. All parts processed in precision to ensure lathe work in good performance.

2. The ultrasonic frequency quenched guide-ways have good wear-resistance.

3. The gears have been quenched and ground by grinding machine.

4. The spindle adopts two-supporting structureand runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made ofhigh quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safetydevices such as braking system, emergency power-off switch and overloadprotection system.

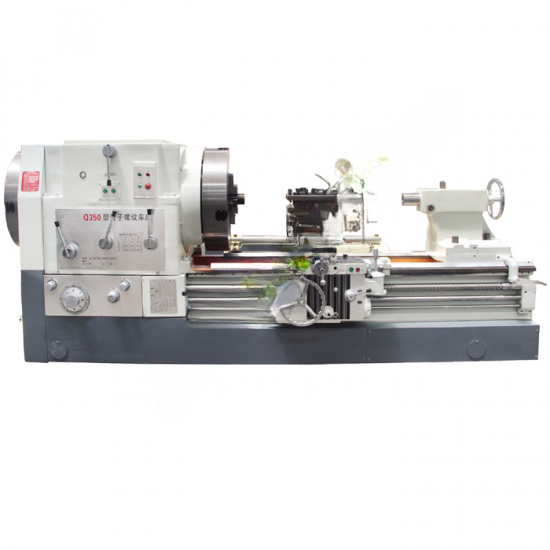

Pipe threading lathe machine Q350

Main Features:

1. All parts processed in precision to ensure lathe work in good performance.

2. The ultrasonic frequency quenched guide-ways have good wear-resistance.

3. The gears have been quenched and ground by grinding machine.

4. The spindle adopts two-supporting structure and runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made of high quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safety devices such as braking system, emergency power-off switch and overload protection system.

Pipe threading lathe machine QK1327

Pipe threading lathe machine QK1319

Pipe threading lathe machine QK1338

Manual Surface Grinding Machine MJ7115 |

| Features: 1. Surface grinding is designed to grind various horizontal and vertical surfaces of the workpieces and endfaces of the grinding wheel. 2. It can also grind various contoured workpieces with shaped wheel or crafts manship apparatus. 3. Integrated grinding head of high quality, high rigidity and accuracy. 4. Small size, light weight,easy operation & maintenance. 5. Centralized lubrication for oil pump. 6. Super slide table 7.Enclosed cabinet style stand 8.Swarf guard 9.One shot lubrication 10.Diamond wheel dresser with holder 11.Tool Box 12.Wheel balancing kit 13.Single phase 3450 RPM motor |

M618A,M820

Manual Surface Grinding Machine M618A,M820 |

| Mainfeatures: 1.Quality castings and Precision ball bearing supporting thespindle 2.Coolant system with nozzle and flow control valve 3.Cast iron machine body and stand for maximum rigidity andsmooth operation 4.The machine can grind all kinds of surfaces or grind complex surfaces by dressing of grinding wheel. 5.The machineis suitable for grinding without auto feed and is installed with permanentmagnetic chuck or electromagnetic chuck according to customer’s requirement. 6.Vertical dial graduations 0.01mm,Cross travel graduations 0.02mm 7.Manual one shot lubrication pump 8.Wheel balancing stand and arbor 9.Halogen work light |

CNC internal grinding machine M2110CNC

| Feature | |

| NC control with English display | |

| Belt driven spindle | |

| lighting system LED type, IP65 | |

| facility of auto lubrication syste for guide ways and screw | |

| coolant tank | |

| coolant flow from work spindle end facility | |

| backlight in operator panel | |

| cross roller guide ways for feeding axis | |

| machine should be suitable for tool rom work and production work | |

| roll dressing system for profril dressing |

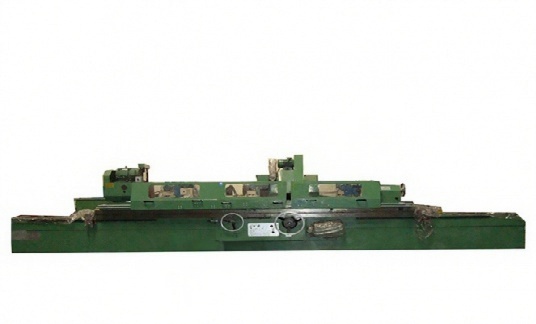

UNIVERSAL CYLINDARCAL GRINDING MACHINE M1408X300

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1420X800

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1450

UNIVERSAL CYLINDRICAL GRINDING MACHINE M1463

| 1.The left and right guide rail adopts P-V structure, which is scraped by high precision manual, sothat the whole system products have high precision and high stability. 2.The front and rear feed guide rail of grinding wheel can choose roller and wire rail structure 3.Classic control mechanism, simple, safe and reliable. 4.M1350, M1450, M1363 series worktable and grinding wheel guide rail adopts high stablehydrostatic guide rail, high rigid dynamic and static pressure spindle. 5.Universal workhead can be adjusted at any Angle within 90 degrees counterclockwise to adapt tochuck grinding internal and external conical workpiece. |

CNC Cylindrical Grinding Machine

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts