KSh0.00

Hydraulic Pipe Bending machine 38NCB,50NCB,63NCB,114NCB,168NCB,325NCB

Oil Country Lathe Machine

Pipe threading lathe machine Q1322

Main Features:

1. All parts processed in precision to ensure lathe work in good performance.

2. The ultrasonic frequency quenched guide-ways have good wear-resistance.

3. The gears have been quenched and ground by grinding machine.

4. The spindle adopts two-supporting structure and runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made of high quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safety devices such as braking system, emergency power-off switch and overload protection system.

Pipe threading lathe machine Q1327

Main Features:

1. All parts processed in precision to ensurelathe work in good performance.

2. The ultrasonic frequency quenched guide-wayshave good wear-resistance.

3. The gears have been quenched and ground bygrinding machine.

4. The spindle adopts two-supporting structureand runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made ofhigh quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safetydevices such as braking system, emergency power-off switch and overloadprotection system.

Pipe threading lathe machine Q245

Main Features:

1. All parts processed in precision to ensure lathe work in good performance.

2. The ultrasonic frequency quenched guide-ways have good wear-resistance.

3. The gears have been quenched and ground by grinding machine.

4. The spindle adopts two-supporting structureand runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made ofhigh quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safetydevices such as braking system, emergency power-off switch and overloadprotection system.

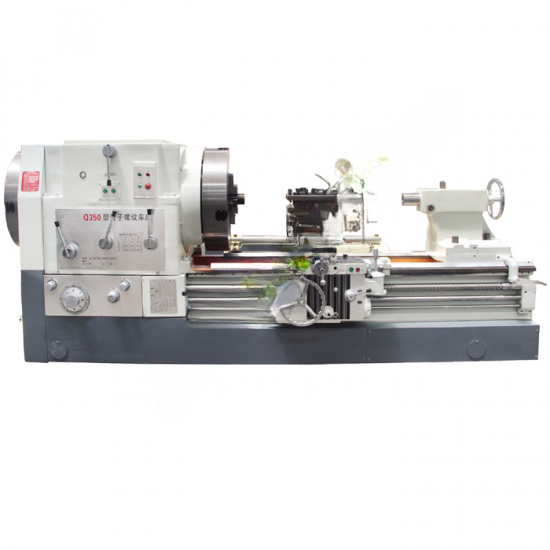

Pipe threading lathe machine Q350

Main Features:

1. All parts processed in precision to ensure lathe work in good performance.

2. The ultrasonic frequency quenched guide-ways have good wear-resistance.

3. The gears have been quenched and ground by grinding machine.

4. The spindle adopts two-supporting structure and runs smoothly and precisely in high speed as all gears properly processed.

5. Headstock, feedbox and apron all made of high quality cast iron, which is casted with resin sand foundry technology.

6. The lathe is equipped with reliable safety devices such as braking system, emergency power-off switch and overload protection system.

Pipe threading lathe machine QK1327

Pipe threading lathe machine QK1319

Pipe threading lathe machine QK1338

M7130A,M7130B,M7130C,M7132

Wheel Head Moving Surface Grinding Machine M7130A,M7130B,M7130C,M7132 |

| Main features: 1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting 2.Grind wheel head spindle front end adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity,specially for heavy-duty cutting. 3.Transmission: Worktable adopts one flat andone V guide ways, driven by hydraulic with smooth movement. 4.Grinding wheel adopts two sets of guideway, one is flat guide way for up/down moving. 5.Another set is swallow tail guide way forback-forward movements, with manual feeding or Auto-feedingby hydraulic cylinder. 6.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank. The temperature of the oil tank raises little so the thermal distortion of the machine is small. 7. Full lubrication system ensuring all guide ways smooth moving. |

M7140A,M7130A

Wheel Head Moving Surface Grinding Machine M7140A,M7130A |

| Main features: 1.Wheel Head moving, Horizontal spindle, suitable for heavy-duty cutting 2.Grind wheel head spindle frontend adopts shell bear bearing support, rear end adopts Roller bearing, with high rigidity, specially for heavy-duty cutting. 3.Transmission: Worktable adopts one flat and one V guide ways, driven by hydraulic with smooth movement. 4.Grinding wheel adopts two setsof guide way, one is flat guide way for up/down moving. 5.Another set isswallow tail guide way for back-forward movements, with manual feeding or Auto-feeding byhydraulic cylinder. 6.The M7130AL,M7140A,M7150A,M7163 series surface grinder adopts the cooler for hydraulic oil tank. The temperature of the oil tank raises little so the thermal distortion of the machine is small. 7.Full lubrication system ensuring all guide ways smooth moving. |

Wheel Head Moving Surface Grinding Machine M7180 |

| Main features: 1. BallLead screw used for forward and back feeding., also worktable 2. Table with Turcite “B” for longer time life. 3. Bigbore oil cylinder adopted for better processing ability. 4. Wheel Head moving type. 5.Individual hydraulic station design. 6. Coolant and complete lubrication available |

M7150A,M7163

Wheel Head Moving Surface Grinding Machine M7150A,M7163 |

| Main features: 1. Ball Lead screw used for forward and back feeding.,also worktable 2. Table with Turcite “B” for longer time life. 3. Big bore oil cylinder adopted for better processingability. 4. Wheel Head moving type. 5. Individual hydraulic station design. 6. Coolant and complete lubricationavailable |

Drill bit grinder KXM10C |

| Main features: 1. Used for grinding of HSS andcarbide engraving cutters with single and multiple flutes in various shapes. 2. The cutters are held by 5C collets in the end mill grinding attachement 3. With the accessories provided the universal D bit grinder can be set up to grind end mills, slot drills and drill bits 4. For more information see the manual 5. Base, wheel mount, grinding wheel, operating tools, manual, spare parts list, test certificate, collets 3,4, 6, 8, 10mm |

Universal Tool Grinder Machine LTG200 |

|

Features: 1.For grinding of various tools, e.g. drills, millingcutters, turning tools etc. 2.Stand serially equipped with tool rest. 3.Large number of standard accessories. 4.Solid construction for vibration-free run. 5.Ergonomically arranged control elements. 6.Universal Grinder for grinding various tools, likedrills, milling cutters, turning tools, etc. 7.Wide range of applications. 8.Extensive accessories included. |

Universal Tool or drill bit Grinding Machine TG-32N |

| Features: 1) Grinding drill bits,step drill,tap,end mill face,round bars fast and accurately. 2) Grinding capacity: Dia.3mm-Dia.32mm/76mm(straight shank:3mm-32mm;Taper shankMT5#:3mm-76mm) 3) Adopts precision 6 jaw self-centering chuck. 4) When 6 jaw chuck is dismantled,the spindle hole MT5# can hold max.76mm taper shank drills. 5) Double cams adopted to save the time for changing & repairing the wheels.end mill,R type cutters and etc. |

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts