0

0 items

KSh0.00

No products in the cart.

Cross slide table AKP series 201,202,203,204,205

Available on backorder

Main features:

1.Worktable surface material is made of cast #250.

2. leadscrew exposed and it’s idle stroke 0.06mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

Add to Wishlist

Add to Wishlist

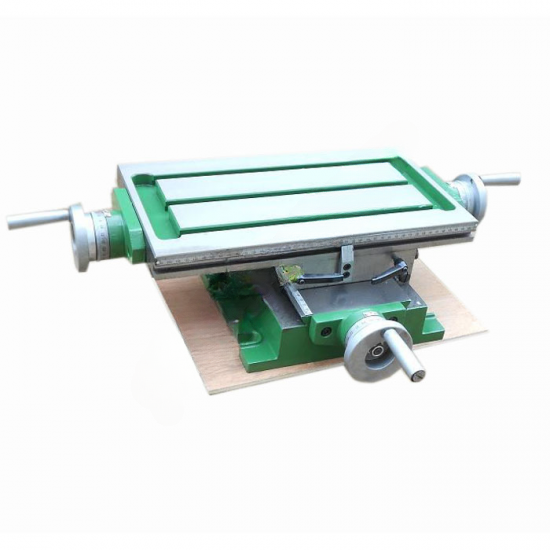

Compound table AKB series AKB-1,AKB-2,AKB-3

Available on backorder

Main features:

1.Worktable surface material is made of cast #250.

2. leadscrew idle stroke 0.06mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

5.model AKB-1only can rotate on X axis,

AKB-2 andAKB-3 can rotate on X and Y axis.

6.modelAKB-3 have handls,easy operation.

Add to Wishlist

Add to Wishlist

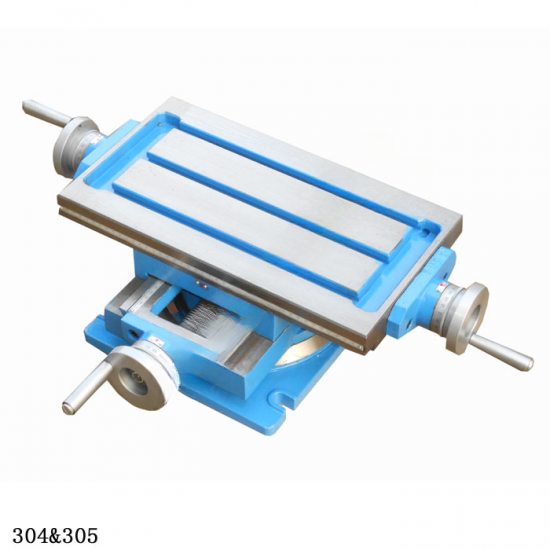

Cross slide table swivel base AKP-1 series 302,303,304,305

Available on backorder

Main feature:

1.Worktable surface material is made of cast #250.

2. With exposed leadscrew and it’s idle stroke 0.06mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

5.rotate in Horizontal plane by 360 degree

Add to Wishlist

Add to Wishlist

Precision cross slide table AKP-2 series 204,205,206

Available on backorder

Main features:

1.Worktable surface material is made of cast #250.

2. leadscrew idle stroke 0.06mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

5.High precision

Add to Wishlist

Add to Wishlist

Precision cross slide table BF series BF16,BF20

Available on backorder

Main features:

1.Worktable surface material is made of cast #250.

2. leadscrew idle stroke turning 0.1mm per 3 graduation.

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

5.The swallow tail of work table is 60 degree.

6.leadscrew nut is made of Ductile Cast Iron.

Add to Wishlist

Add to Wishlist

Cross slide table TC18

Available on backorder

Features:

1.Worktable surface material is made of cast #250.

2. leadscrew idle stroke 0.05mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

Add to Wishlist

Add to Wishlist

CNC cross slide table with stepper motor 206-B

Available on backorder

Main Features:

1.Worktable surface material is made of cast #250.

2.Ball leadscrew idle stroke 0.06mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

5.stepper motor

Add to Wishlist

Add to Wishlist

Cross slide table with power feed 206-Z

Available on backorder

Main Features:

1.Worktable surface material is made of cast #250.

2. Ball leadscrew idle strokeis 0.06mm

3.X,Y axis reticle tolerance is 0.05mm

4.surface parallelism is 0.03mm/100mm

5. stepless speed

Add to Wishlist

Add to Wishlist

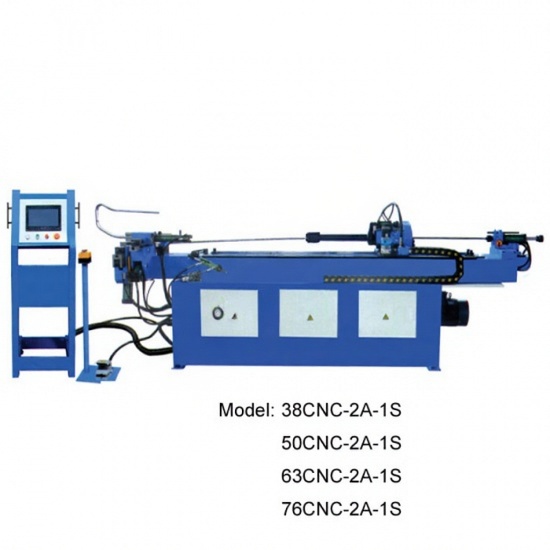

CNC Single Head Pipe Bending Machine 38;50;63;76CNC-2A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, hydraulic bending.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-4A-2S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating,servobending, servo moving die.

18.Double-layer mold.

Add to Wishlist

Add to Wishlist

CNC Pipe Bending Machine 18;28;38;50;63;76;89;114CNC-3A-1S

Available on backorder

Features: (CNC)

1.Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2.Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc.

3.Controlled through PLC and possesses manual, semi-automatic and full-automatic functions.

4.Y, B, C three coordinates of motion under precision control by industrial computer realizing full-auto mandrel on or mandrel off rapid bending.

5.Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

6.About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

7.Various Touch screen language are available for choice as per request.

8.Adoption of hydraulic valve and oil way board can control actions individually to prolong the lifespan of hydraulic parts.

9.Guiding module has auxiliary pushing function and at the same time it possesses reiteration and entering repeat functions that can make the guiding module length shorten.

10.Counter function can accurately count work piece’s quantity and save data whether in power-on or power-off situation.

11.Auto lubrication system to protect components and improve the working lifeof machine.

12.Possess automatic error detection function and limit protecting function,removing or changing faults easily and quickly.

13.Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient.

14.Optional function of core reversing slowly.

15.Optional function of slow bending.

16.Optional function of anticipated mandrel extraction.

17.Servo feeding, servo rotating, servobending.

Add to Wishlist

Add to Wishlist

Gap bed lathe machine GH1440K

Available on backorder

Main features:

1. Induction hardened, precision ground V-way bed.

2. D1-4 spindleis supported by high quality tapered roller bearing.

3. Hardened,precision ground gears in headstock.

4. High precision directly mounting chuck.

5. Carriage mounted spindle control lever.

6. Automatic feed and threading are fully interlocked.

7. Tailstock maybe offset for turning tapers.

8. One-piece casting iron base allows heavy cuts.

9. Tolerance test certificate, test flow chart included.

Add to Wishlist

Add to Wishlist

Gap Bed Lathe Machine CQ6236

Available on backorder

Main features:

1.2 Axis digital readout system

2.Quick change toolpost with 5 holders

3.Concertina leadscrew cover

4.Gear drive headstock for quick change of spindle speeds

5.Precision V-beds are hardened and ground, incorporating a rigid webbed casting

6.Foot operated spindle brake with safety cut out switch

7.Change gears for metric and imperial thread cutting

8.Adjustable taper roller bearings support the spindle

9.Inching button is incorporated on the control panel for convenient spindle speed selection

10.Enclosed quick action gearbox for thread cutting and auto feeding

11.Powered longitudinal and cross feeds

12.D1-5 camlock spindle for quick chuck changes and safe reverse-direction turning. ISO standard

13.Removable gap bed-way for larger diameter jobs

Add to Wishlist

Add to Wishlist

Gap bed lathe machine GH1440A

Available on backorder

Main features:

1. Gear drive headstock for quick change of spindle speeds

2. Cast iron stand increasing rigidity and reducing vibration

3. Precision V-beds are hardened and ground, incorporating a rigid webbed casting

4. Low voltage work light

5. Foot operated spindle brake with safety cut out switch

6. Slide out front swarf tray for easy cleaning

7. Change gears for metric and imperial thread cutting

8. Oil sight glass for head stock and gearbox

9. Adjustable taper roller bearings support the spindle

10. Overload clutch mechanism on auto power feed

11. Micro-adjustable length-stop onbed-way for accurate repetitive operation

12. 3.2HP/415V motor 16-speed(50-2000rpm)

13. Inching button is incorporated on the control panel for convenient spindle speed selection

14. Enclosed quick action gearbox for thread cutting and auto feeding

15. Powered longitudinal and cross feeds

16. D1-4 camlock spindle for quick chuck changes and safe reverse-direction turning. ISO standard

17. Removable gap bed-way for larger diameter jobs

18. Dual calibrated dials (except for saddle hand-wheel)

19. Chuck & change gear guards are fitted with micro switches

20. Coolant system with flexible hose

21. Slide out swarf tray

Add to Wishlist

Add to Wishlist

Gap bed lathe machine CH series

Available on backorder

Main features:

1. Very rigid machine bed withheavy ribbing

2. Wide V-guide,induction-hardened and precision-ground

3. Maximum accuracy and quietoperation even at high speeds

4. High machining performance withheavy-duty powerful main drive

5. Infinitely variable slip clutchallows working with stops

6. Universal gearbox allowscutting of inch, metric threads, modular & diametral pitches

7. Accurate tested according toDIN 8606, best surface roughness of 1.6 um / N7 according to DIN 1302

8. Removable gap bridge formachining of large diameter parts

9. Large spindle Capacity diameter80 mm for machining of long parts

10. To ensure maximum accuracy andsmooth operation at high speeds

11. The main spindle is dynamicallybalanced and supported by adjustable precision bearing

12. Camlock ASA D1-8 mount accordto DIN 55029

13. Centre lubrication pump for CAMbox and box way

14. Includes Time-Saving FootBrakes

15. Pull-out Chip Tray

16. Headstock gears run in an oilbath

17. Micrometer Stop

18. Full length splash guard

19. Foot brake

20. Coolant system

21. Halogen work lamp

22. Jog button and emergency stop

Add to Wishlist

Add to Wishlist

Gap Bed Lathe Machine C6246

Available on backorder

Features

1.2axis digital readout system

2.Quickchange tool post

3.Triplebearings supporting headstock spindle

4.Adjustabletaper roller bearings providing spindle accuracy

5.PrecisionV-beds & headstock gears are all hardened & ground

6.Onepiece cast iron base increases rigidity

7.Overloadprotection on drive motor and coolant system

8.Universalenclosed gearbox incorporating metric & imperial thread capabilities

9.Inchingbutton incorporated on the control panel for convenient spindle speed selection

10.Footoperated spindle brake with safety cut out switch

11.300mmwide induction hardened heavy duty cast iron bed

12.Removablegap bed allowing work piece to swing up to 640mm

13.Chuckguard fitted with safety micro switch

14.Poweredlongitudinal and cross feeds

Add to Wishlist

Add to Wishlist

UK Office

Prestige Industrial Services Uk Ltd, 38 Beacon Buildings Leighswood Road, Aldridge Walsall West Midlands, WS9 8AA United Kingdom

TEL: +441922277452

MOBILE: +441922277452

EMAIL: salesuk@pindustrial.co.uk

Kenya Office

12 Dar-Es-Salaam Road Opposite Enterprise Road Post Office Industrial Area P.O. Box 18681-00500-Nairobi Kenya

TEL: +254 020 7760074

MOBILE: +254 780 202 426

EMAIL: sales@pindustrial.co.ke

Policies & Key Information

Store Information

- Machinery Shop

- CNC Machines

- Milling Machine

- Drill Machine

- Grinding Machine

- Metal Sheet Machine

- Measuring Tools

- Auto-Maintenance Equipment

- Machine Tool Cabinet

- Gear Hobbing Machine

- Lathe Machine

- Machinery Accessories

- Adjustable angle Plate

- Boring heads

- CNC tool systems

- Quick Change Tool Post

- Cross Table

- Clamping Kit

- Center drill

- Digit Read Out

- Dividing Head

- Drill Chuck

- Edge finder

- Electric power feed

- End Mill Cutter

- face mill cutter

- H.V. Rotary work table

- Lathe chuck

- Liver Center

- Machine Vice

- Magnetic chuck

- Milling Chuck Sets

- Pipe Bending Machine

- Logistic and Warehouse Equipment

- Pipe Threader Machine

- Press Machine

- Sawing Machine

- Shaping Machine

- Slotting Machine

- Welding Machine

- Wood Working Machine

- Tools Shop

- Products Shop

- Technical Services

- Our Market

- Contacts